Installation/Usage

Instructions

- Servo Spacers

- Swash Leveling Zip Tools

- Micro Servo 90 Degree Tool

- Mini Servo 90 Degree Tool

- Standard Servo 90 Degree Tool

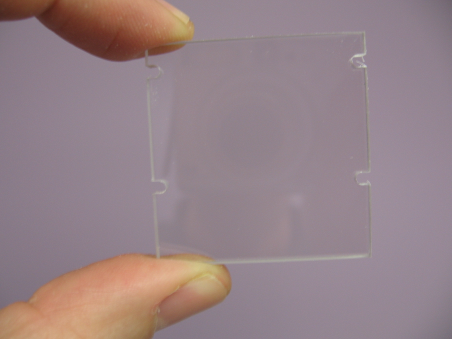

- 3.5 mm Under Swash Leveling Tool (USLT)

Patent Pending

- 5 mm Under Swash Leveling Tool (USLT) Patent

Pending

- 8 mm Under Swash Leveling Tool (USLT) Patent

Pending

- 10 mm Under Swash Leveling Tool (USLT)

Patent Pending

- 12 mm Under Swash Leveling Tool (USLT)

Patent Pending

- 14 mm Under Swash Leveling Tool (USLT)

Patent Pending

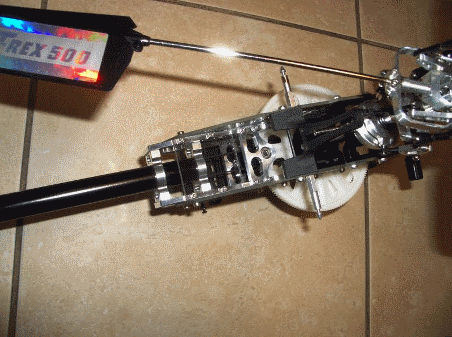

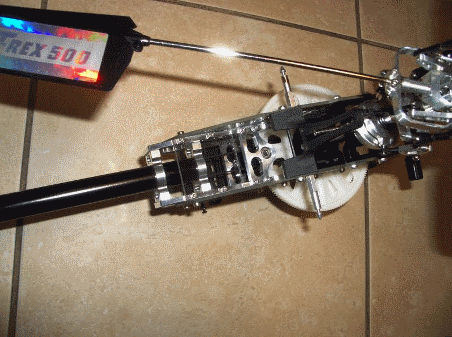

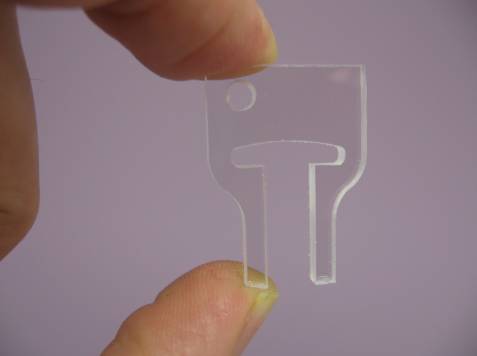

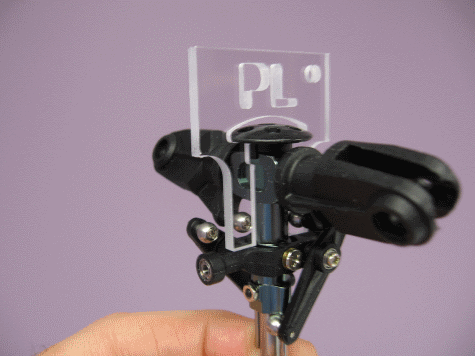

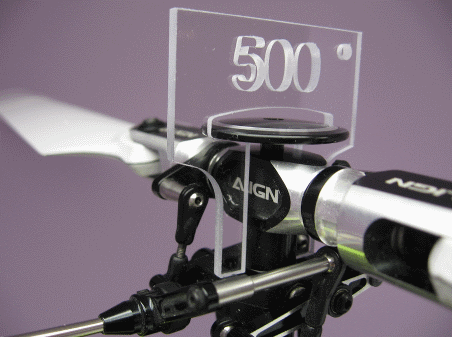

- Universal 250 - 450 Zero Pitch Tool

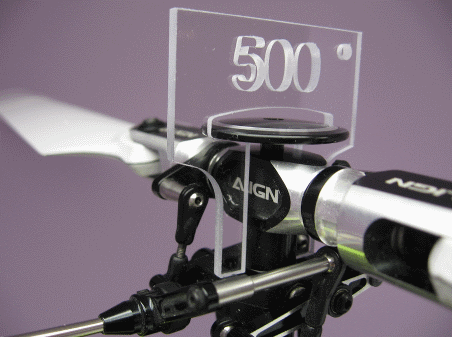

- Universal 500 - 700 Zero Pitch Tool

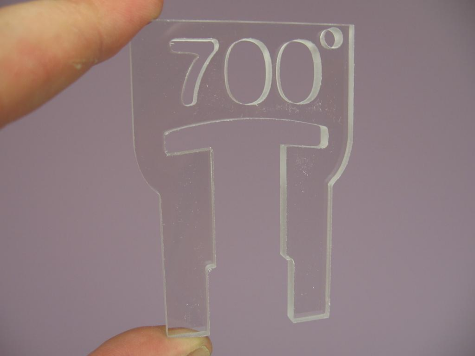

- TREX 700 Zero Pitch Tool

- Logo 400 Zero Pitch Tool

- Logo 500 Zero Pitch Tool

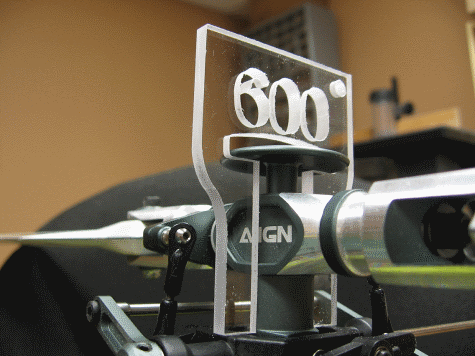

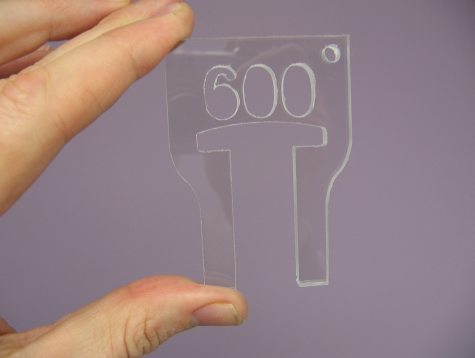

- Logo 600 Zero Pitch Tool

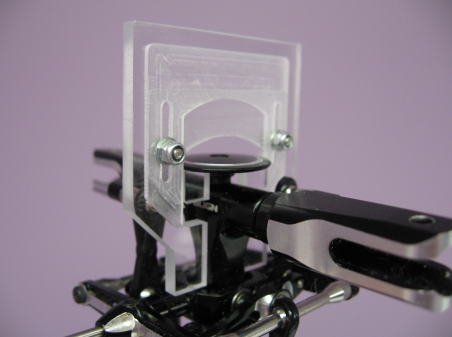

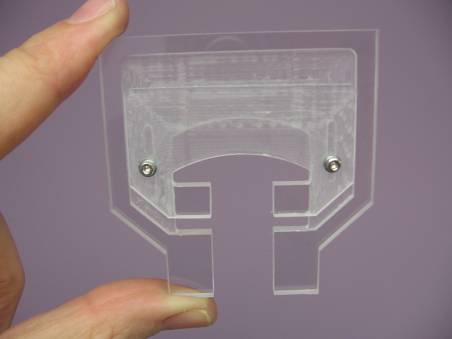

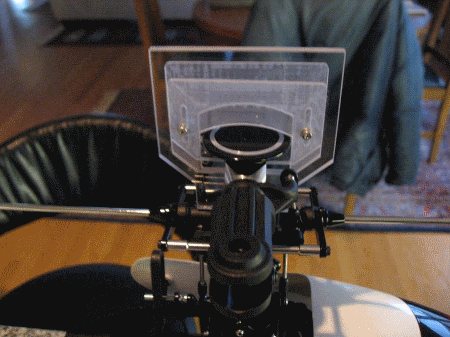

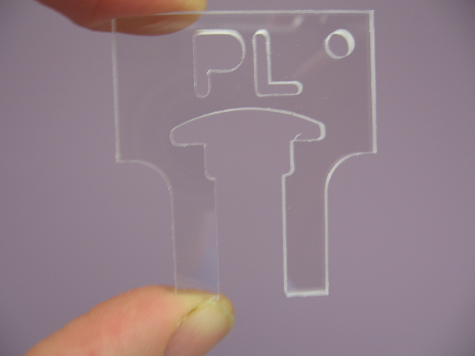

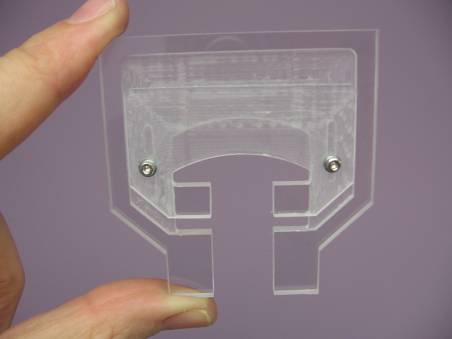

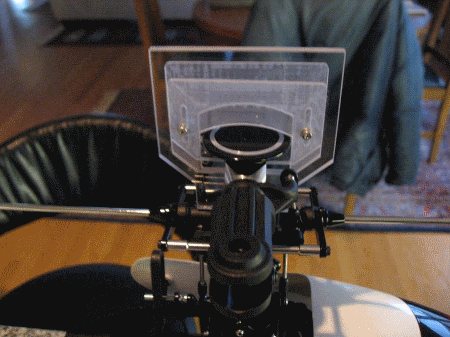

- TREX 500 FBL Pitch Alignment Tool

- TREX 600 FBL Pitch Alignment Tool

- Logo FBL Pitch Alignment Tool

- Compass 6HV FBL Pitch Alignment Tool

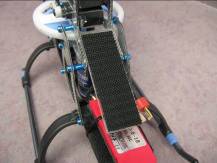

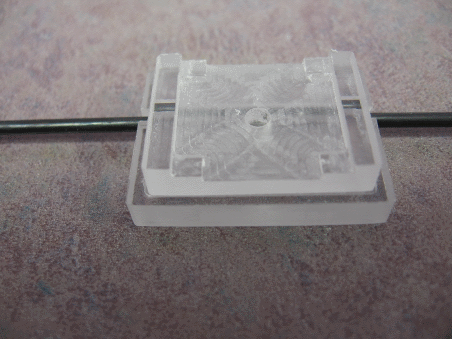

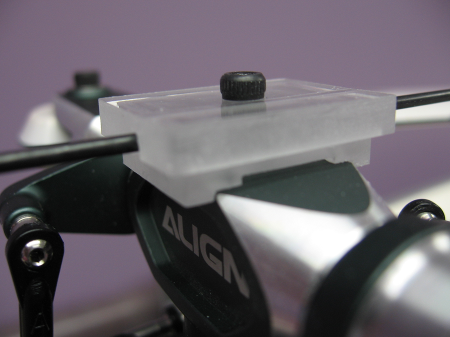

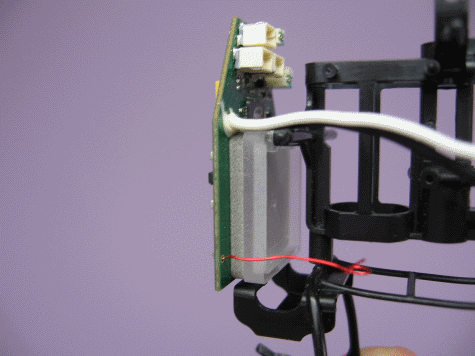

- TREX 450 Sport Gyro/Receiver Mount

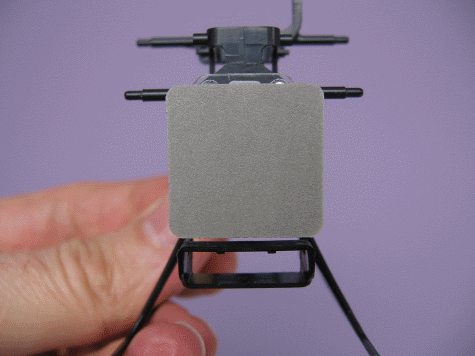

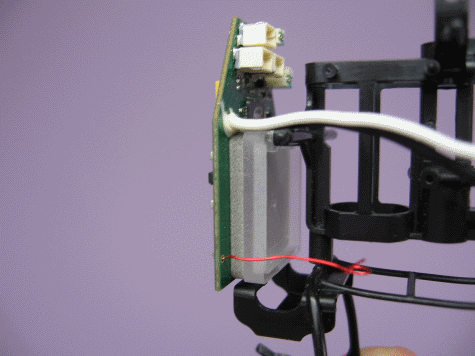

- TREX 500 Gyro/Receiver Mount

- TREX 500 VBAR Mount

- Rush 750 Satellite Receiver Mounts

- mCP X 3-n-1 Mount (for Controller

Module)

- Ultimate TREX 500 Gyro Mount

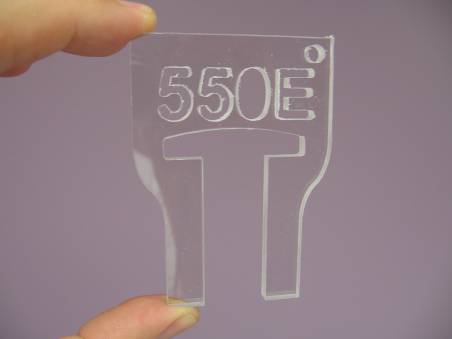

- Ultimate TREX 550E/600E Gyro Mount

- Ultimate TREX 550N/600N Gyro Mount

- TREX 600 Gyro/Receiver Mount

- TREX 600 VBAR Mount

- TREX 450 Battery Mount

- TREX 500 Battery Mount

- Inverted Gyro Mount (The Thingy)

- Gaui 200 Gyro/Receiver Mount

- TREX 250 Flybar Lock

- TREX 450 Plastic Flybar Lock

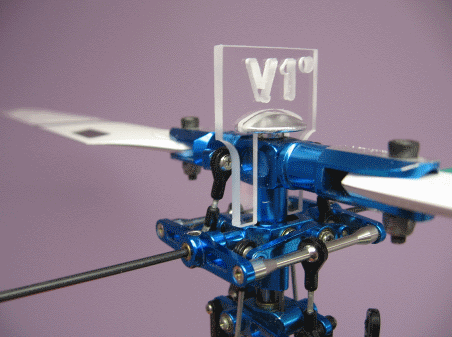

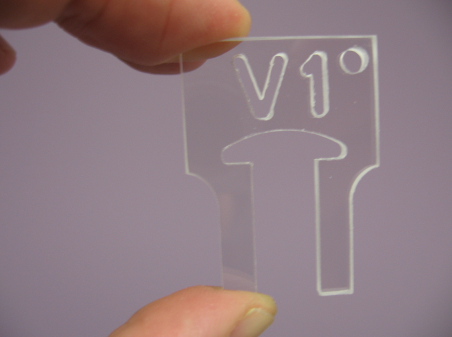

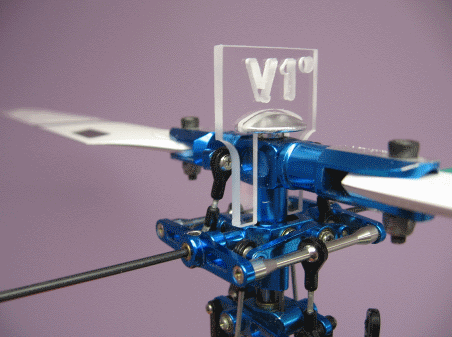

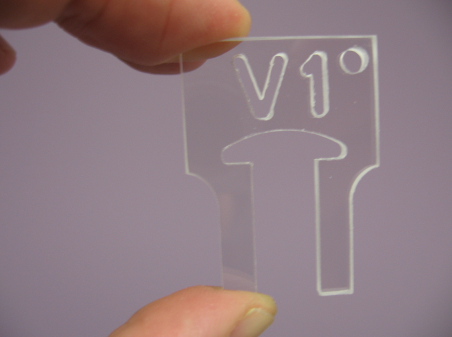

- TREX 450 V1 Flybar Lock

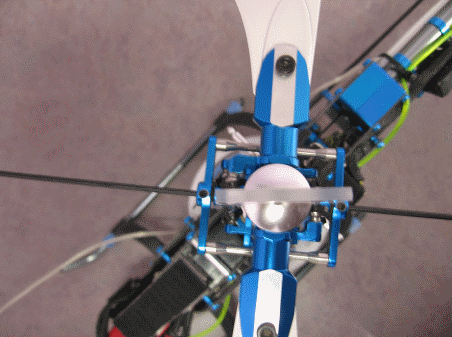

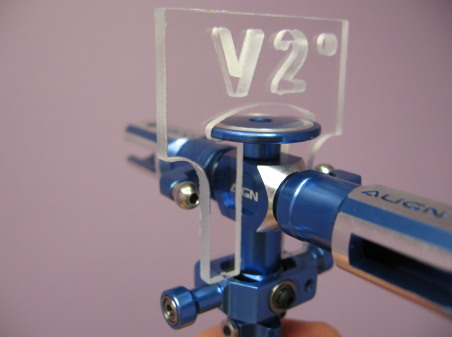

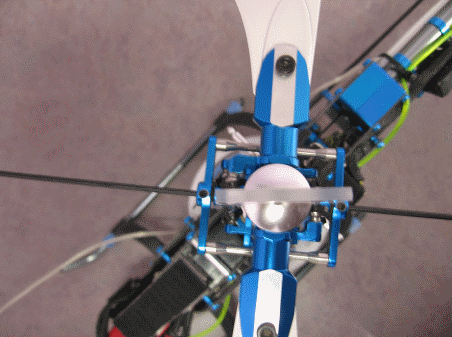

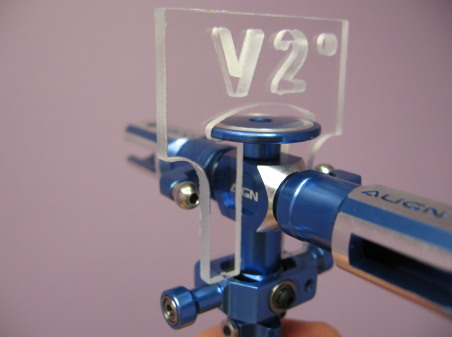

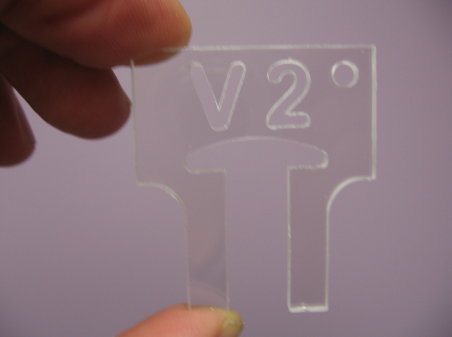

- TREX 450 V2 Flybar Lock

- TREX 450 Sport Flybar Lock

- TREX 450 Pro Flybar Lock

- EXI 450 Flybar Lock

- Adjustable 450 Flybar Lock

- Adjustable 500 Flybar Lock (Fits TREX 500

series and similar heads)

- TREX 500 Flybar Lock (fits heads with

plastic seesaw)

- TREX 500 ESP Flybar Lock (fits heads with

the metal seesaw)

- TREX 500E Pro Flybar Lock

- TREX 550 ESP Flybar Lock

- Outrage 550 Flybar Lock

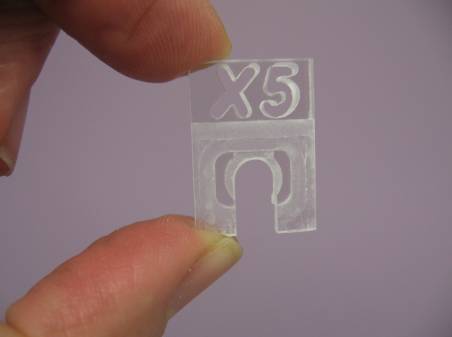

- Gaui X5 Flybar Lock

- TREX 600 Flybar Lock (fits original plastic

and original metal seesaws)

- TREX 600 ESP Flybar Lock (fits latest

lighter metal seesaws)

- TREX 700 Flybar Lock

- TREX 450 Night Fins (1 Horizontal and 1

Vertical)

- TREX 450 Night Fins w/Slotted Text (1

Horizontal and 1 Vertical)

- Slotted Finless Fins & 3D Fins

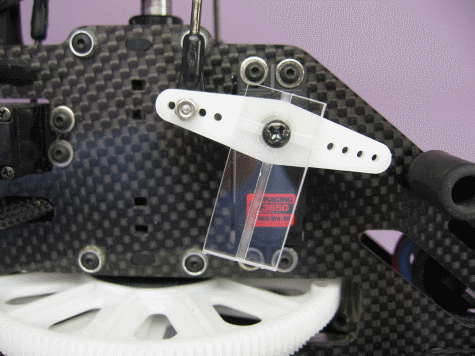

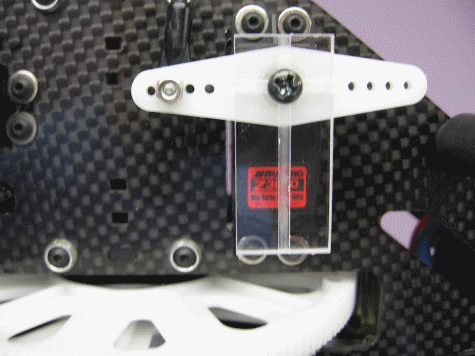

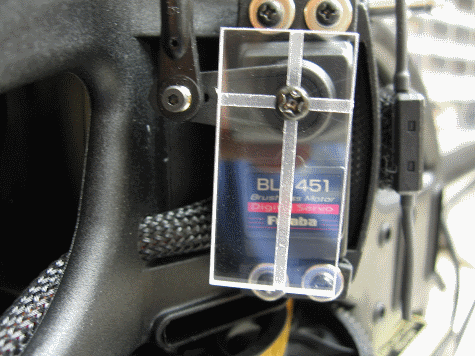

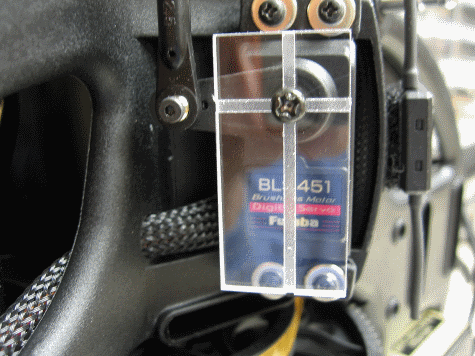

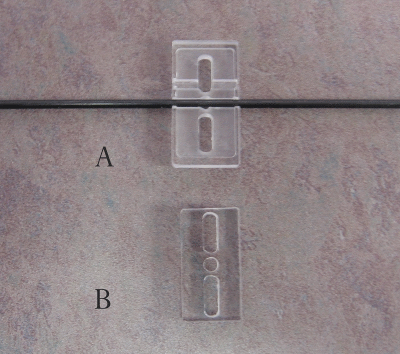

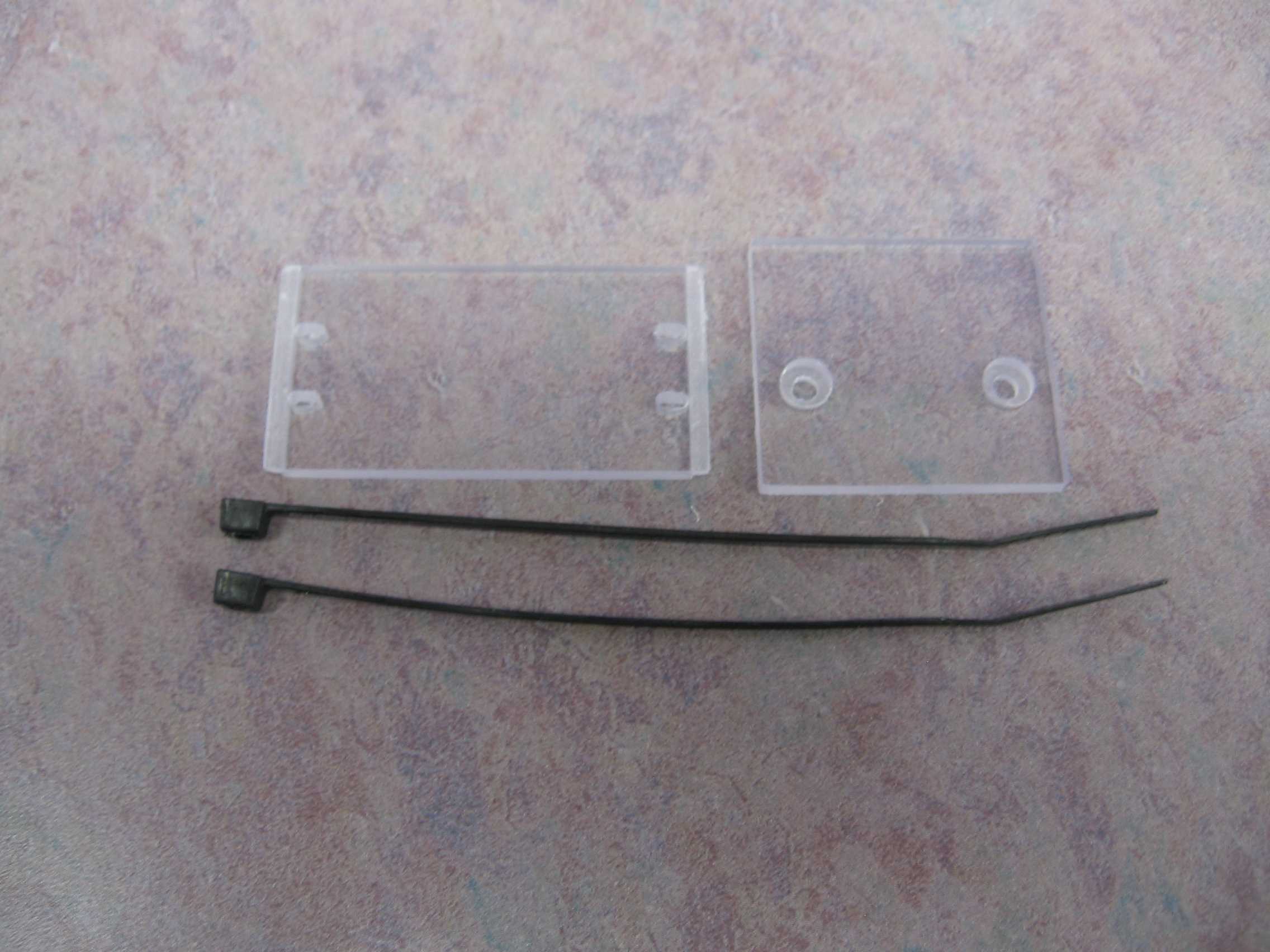

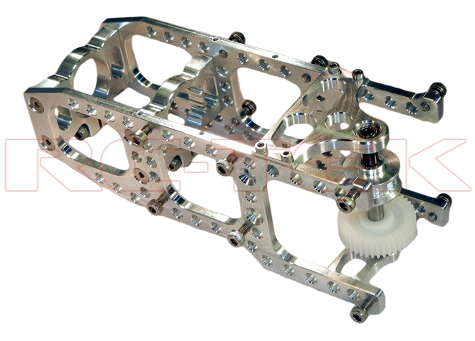

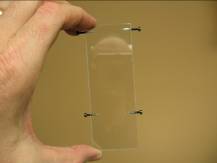

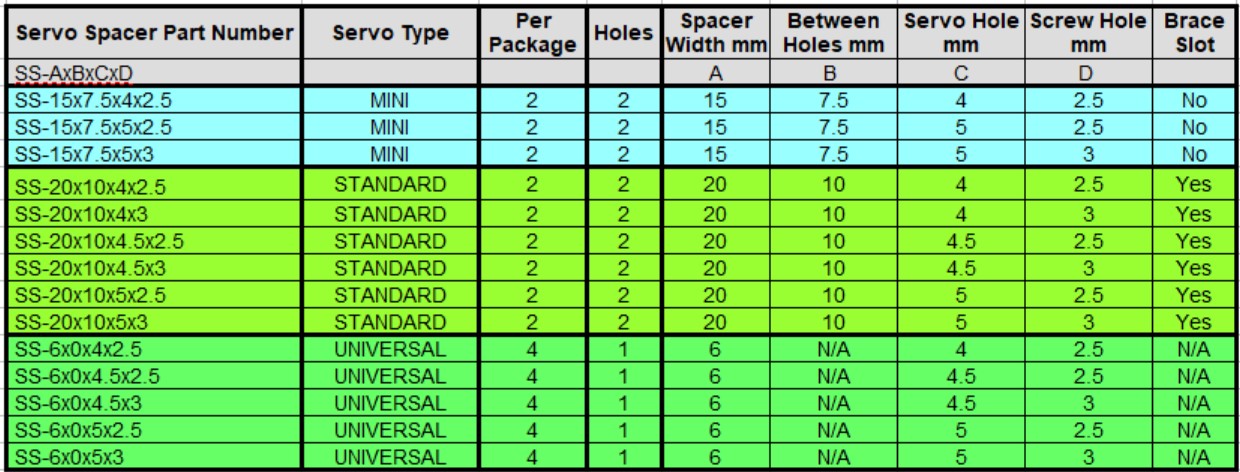

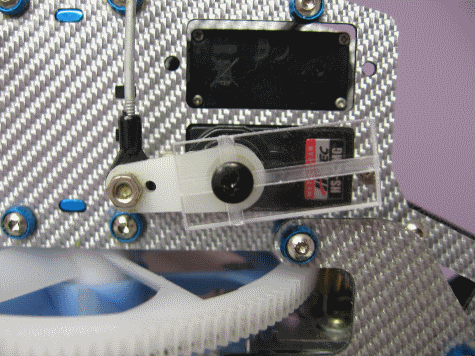

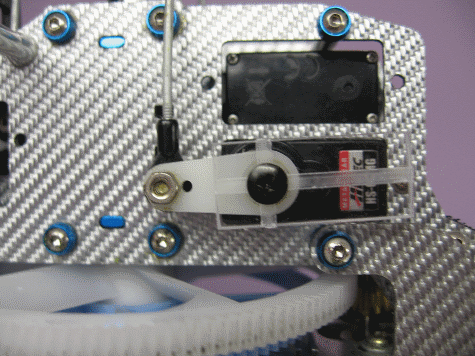

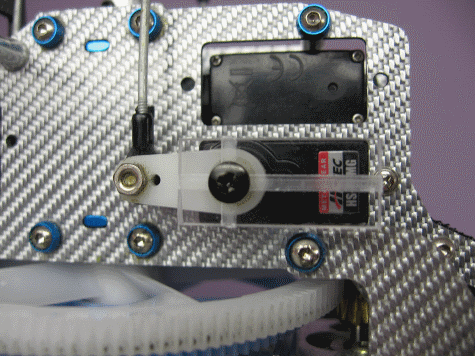

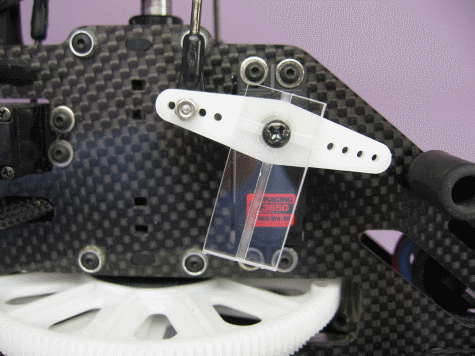

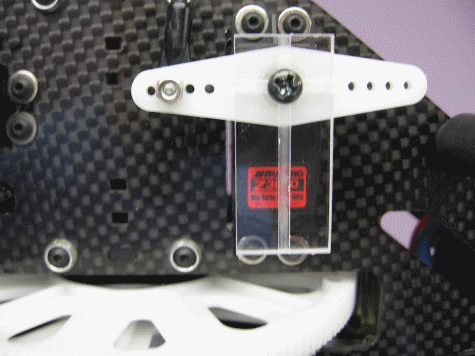

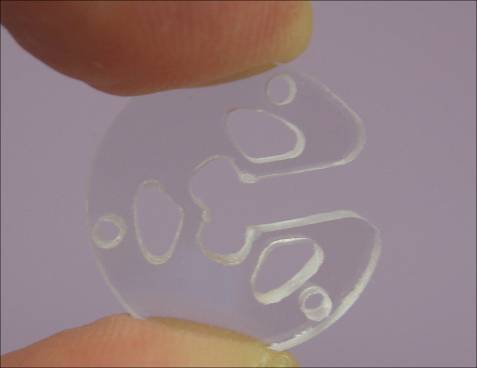

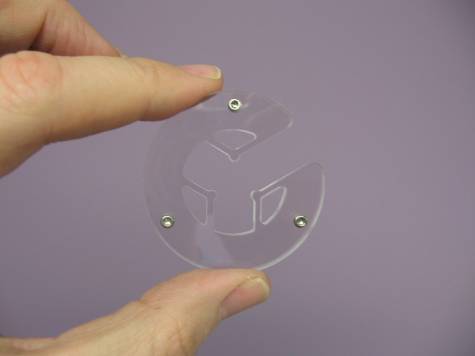

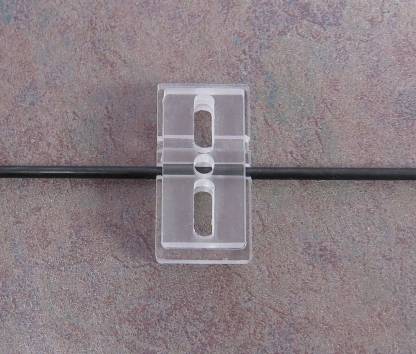

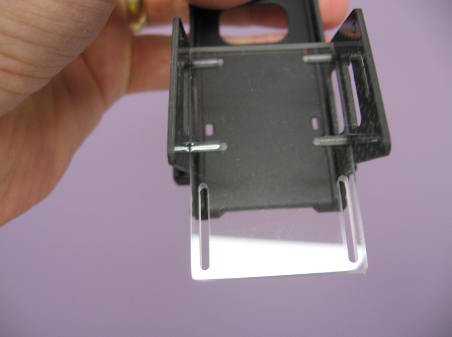

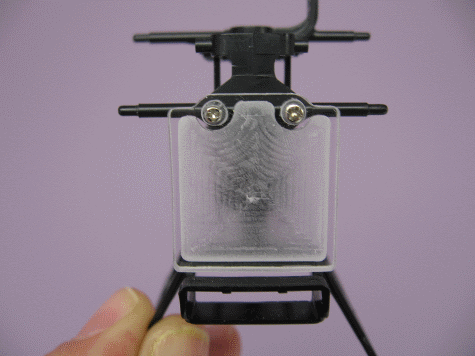

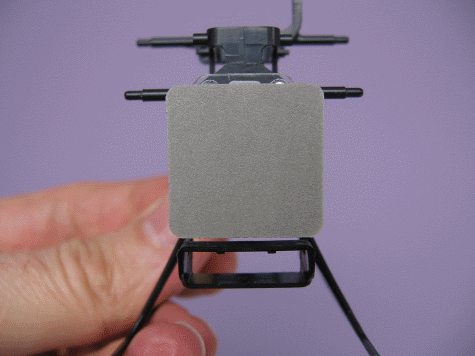

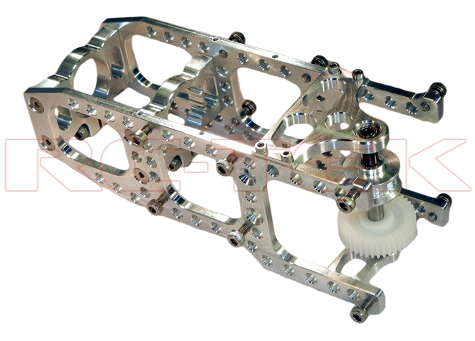

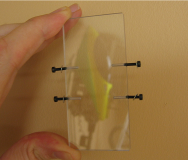

Servo

Spacers

These

spacers allow you to stabilize your servos securely without the stock

rubber grommets. Package of four will mount 1 servo.

Press fit the servo spacers over the servo holes then mount

with existing screws and washers. Tighten screws snugly but do not over

tighten as it is not necessary and it may damage the part and/or the

servo mounting hardware. Match the Servo Spacer part number with the

dimensions of the servo you are mounting. The servo hole size and your

desired screw size are all used to determine which Servo Spacer you

need.

Note:

The Polycarbonate part can be modified with a fine wood file if required

Note:

Let me know if you had to modify the part and I'll make future parts

better.

If you need other sizes, here is a guide to currently supported sizes:

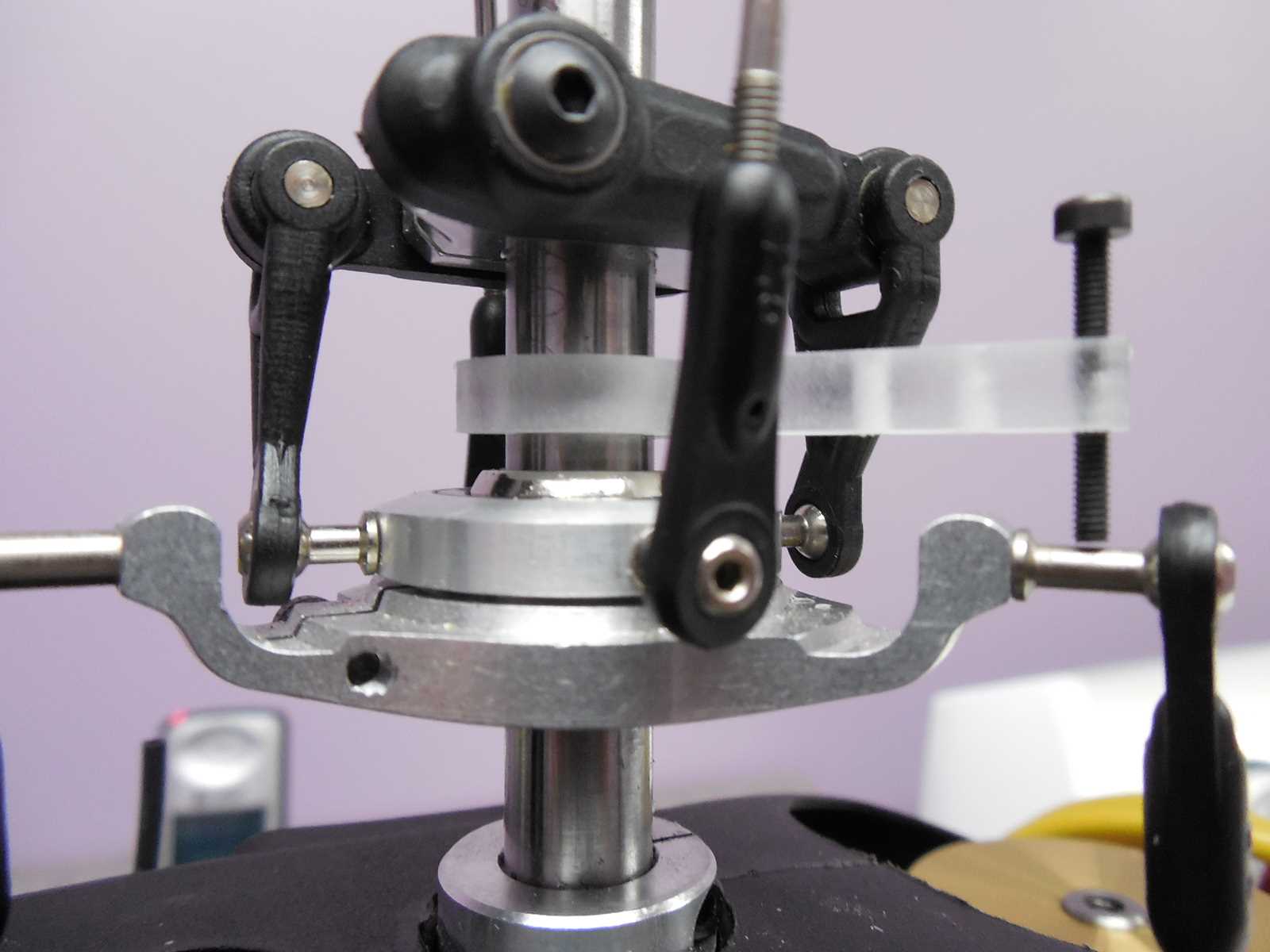

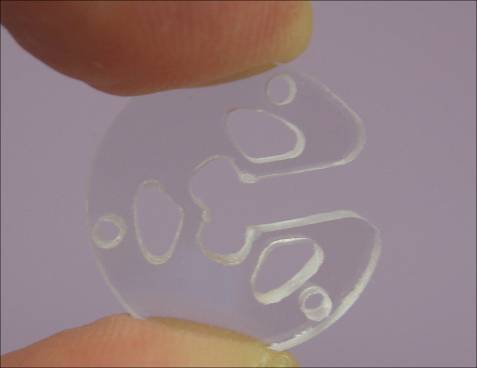

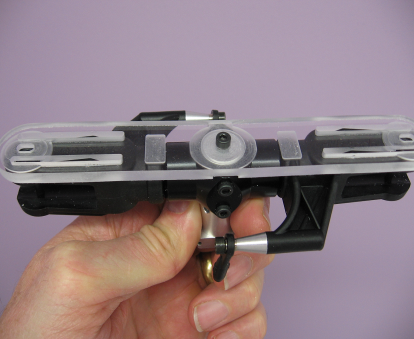

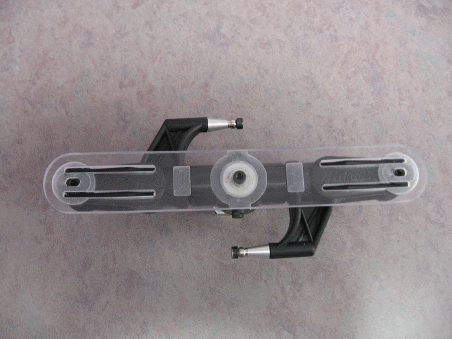

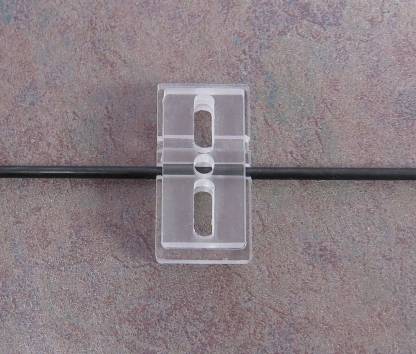

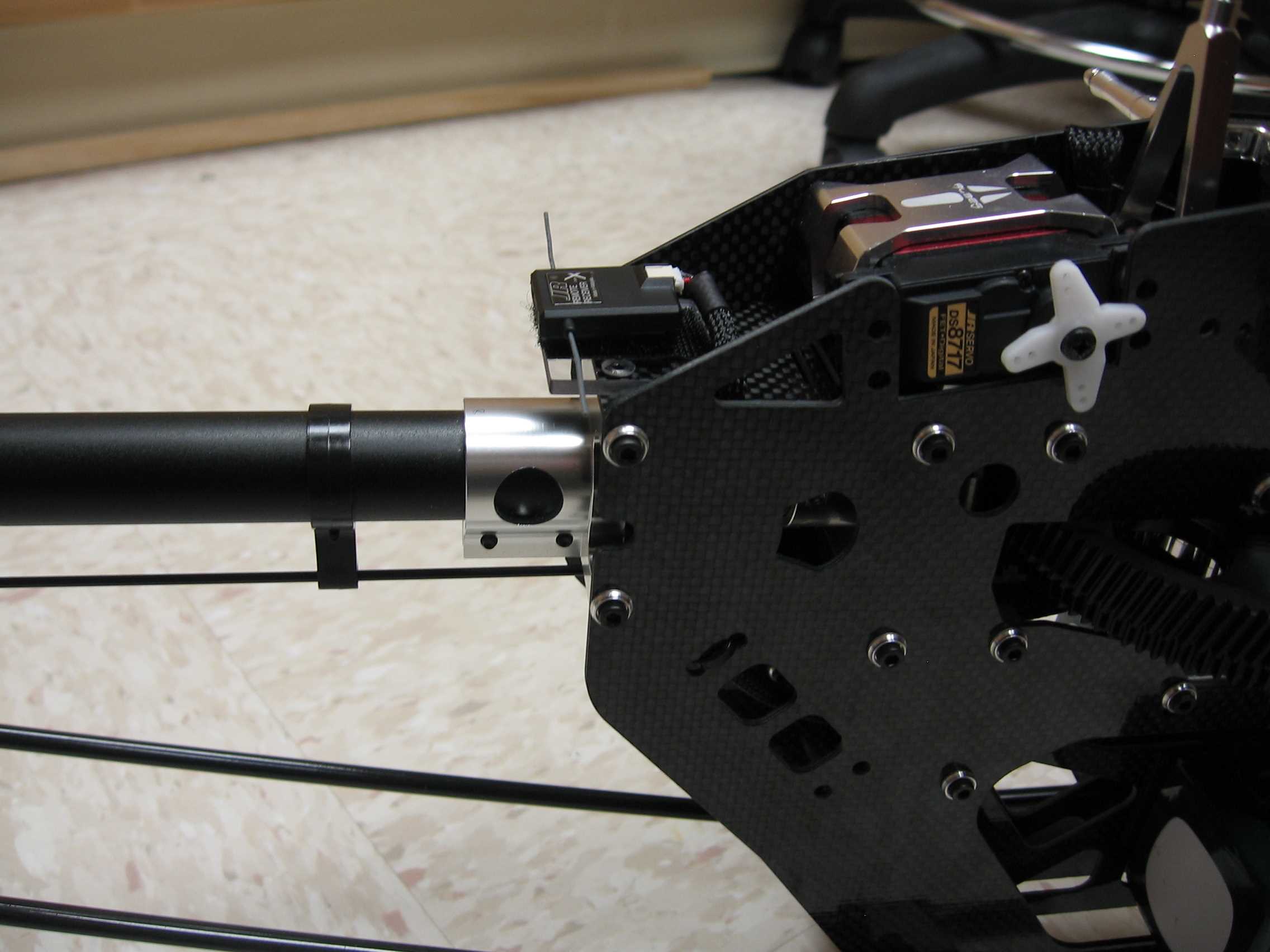

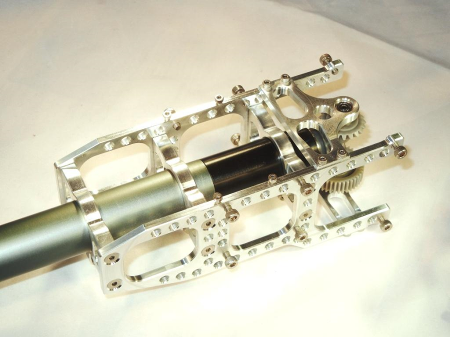

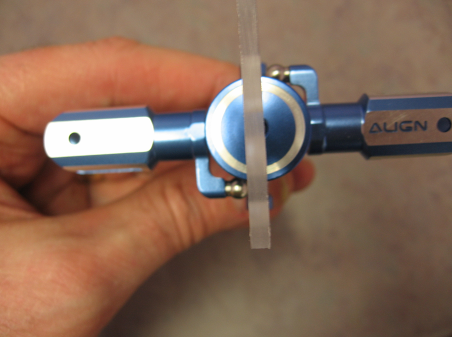

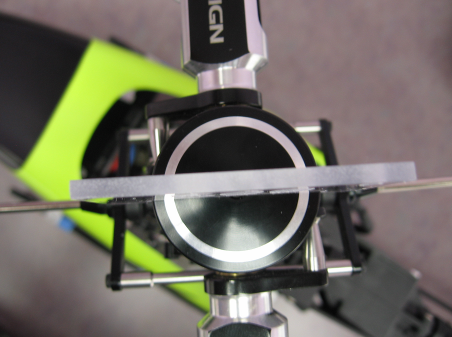

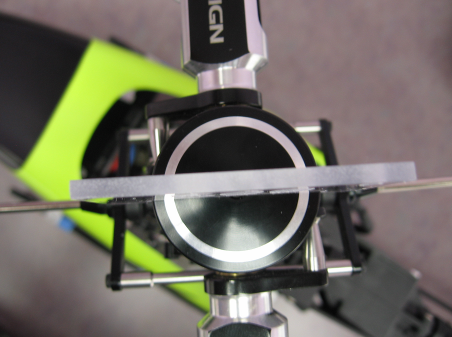

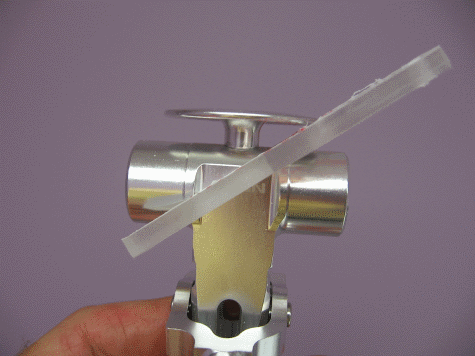

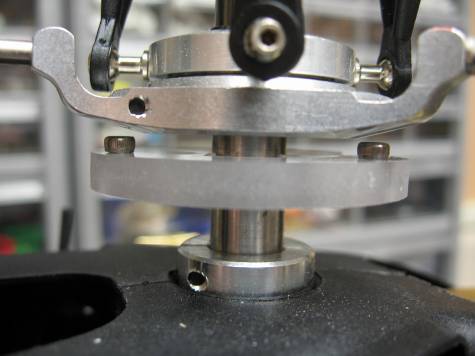

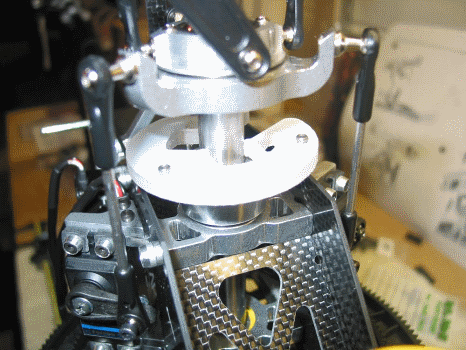

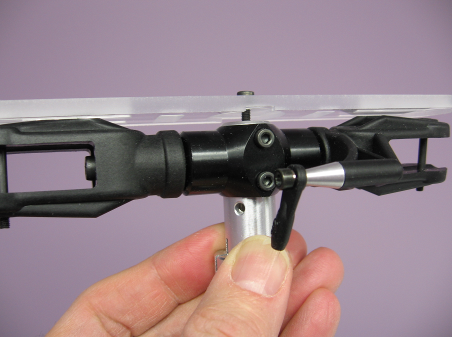

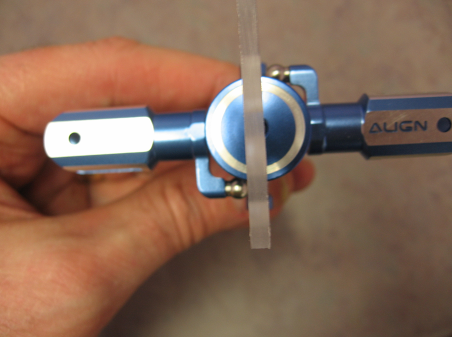

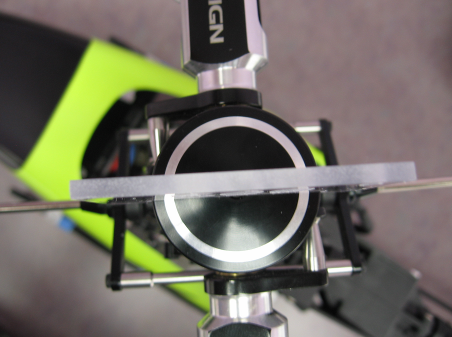

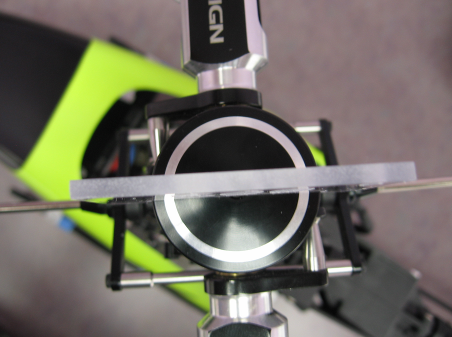

Swash

Leveling Zip Tools Patent

Pending

This tool allows you to level your swash plate WITHOUT

removing the head. Polycarbonate tool won�t scratch your heli.

Press fit the tool onto the main shaft just over the swash

plate and it provides a level surface to use as a reference while leveling

your swash. Once the tool is installed, adjust the contact point to just

touch anywhere on one swash linkage. You can then turn the shaft with the

tool attached and use it to adjust the others to the exact same height.

This tool is similar in concept to a zip tie, but it is easier to attach

and remove and it has an adjustable contact point which allows for optimum

accuracy.

Note: If the Polycarbonate tool can touch any of the swash

linkage, you don�t need to use the adjustment screw.

Note: Measurement can be made to any convenient part of the

swash linkage, not just the spot shown in my picture.

Note: Try using the head side of the screw if the holes don�t

line with what you want to measure.

Note: Do not leave the tool in a flexed state on a main shaft

when not in use.

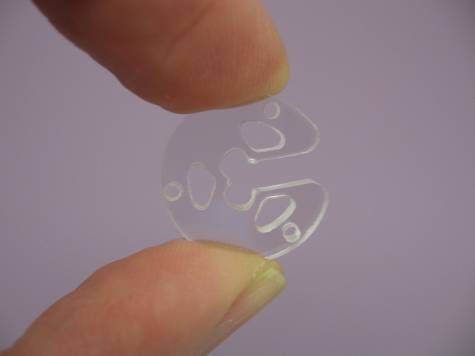

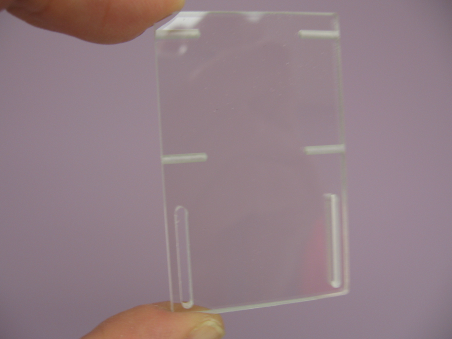

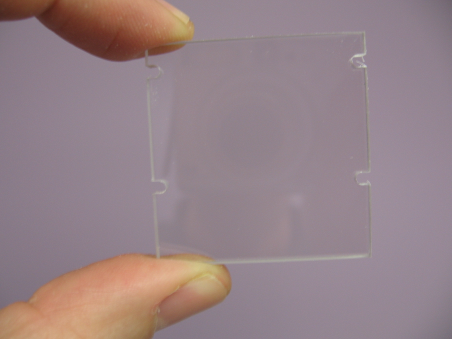

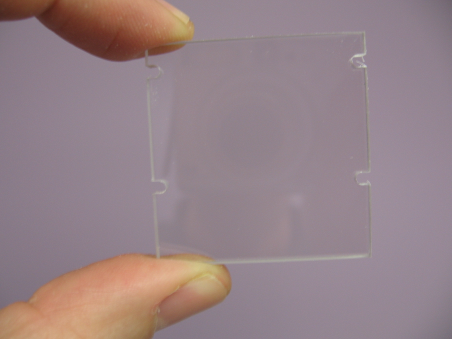

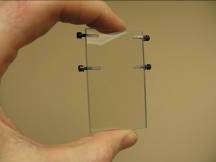

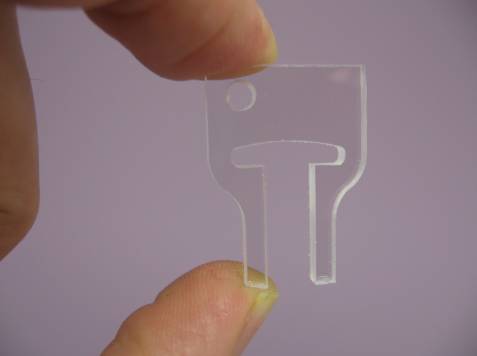

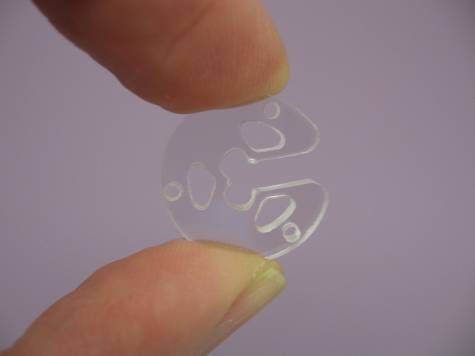

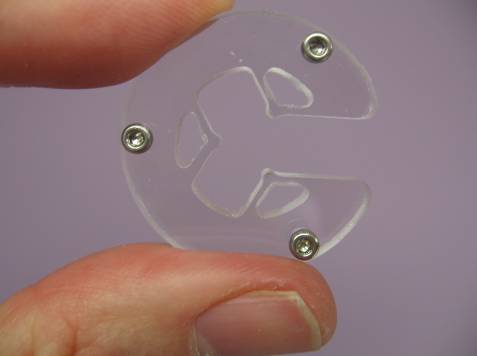

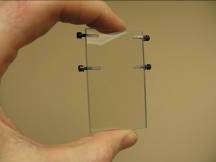

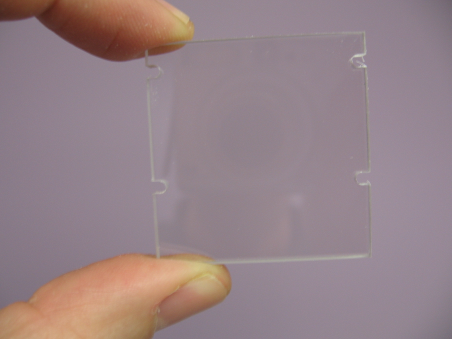

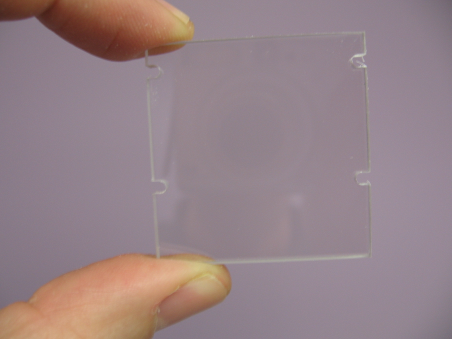

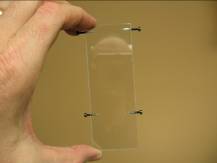

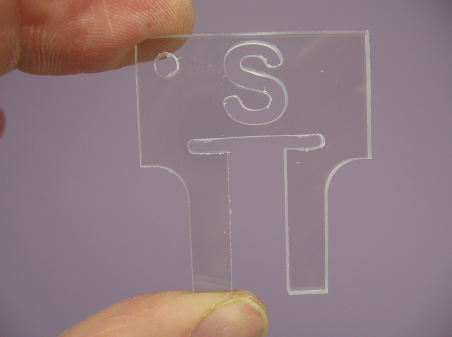

Micro

Servo 90 Degree Tool

This tool to makes it easy to align servo horns at 90 degrees

on your micro size servos. With the shape of many horns, it�s difficult to

eyeball it perfectly without the help of a tool. Lexan tool won�t scratch

your paint.

This tool can be used on or off the heli, with or without

linkages. Line up a slot with the horn holes then snug it down. Use

sub-trim to line up the edge of the tool with the outside edge of the

servo and you are done. It's similar to using a pitch gauge. Flip it over

for servos with the horn on the other side. You may need a longer servo

screw to mount. (not supplied)

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

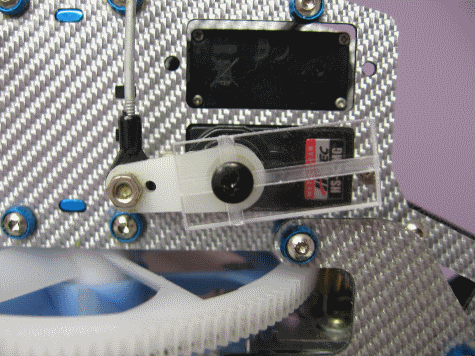

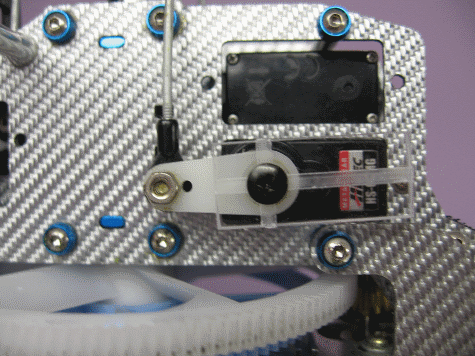

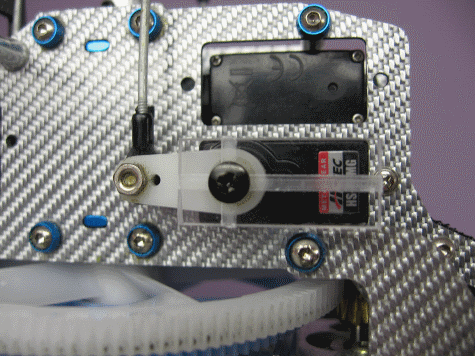

Mini

Servo 90 Degree Tool

This tool to makes it easy to align servo horns at 90 degrees

on your mini size servos. With the shape of many horns, it�s difficult to

eyeball it perfectly without the help of a tool. Lexan tool won�t scratch

your paint.

This tool can be used on or off the heli, with or without

linkages. Line up a slot with the horn holes then snug it down. Use

sub-trim to line up the edge of the tool with the outside edge of the

servo and you are done. It's similar to using a pitch gauge. Flip it over

for servos with the horn on the other side. You may need a longer servo

screw to mount. (not supplied)

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

Standard

Servo 90 Degree Tool

This tool to makes it easy to align servo horns at 90 degrees

on your standard size servos. With the shape of many horns, it�s difficult

to eyeball it perfectly without the help of a tool. Lexan tool won�t

scratch your paint.

This tool can be used on or off the heli, with or without

linkages. Line up a slot with the horn holes then snug it down. Use

sub-trim to line up the edge of the tool with the outside edge of the

servo and you are done. It's similar to using a pitch gauge. Flip it over

for servos with the horn on the other side. You may need a longer servo

screw to mount. (not supplied)

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

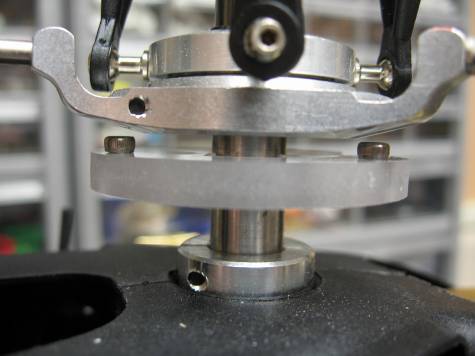

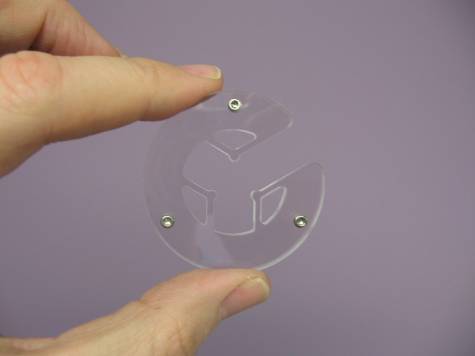

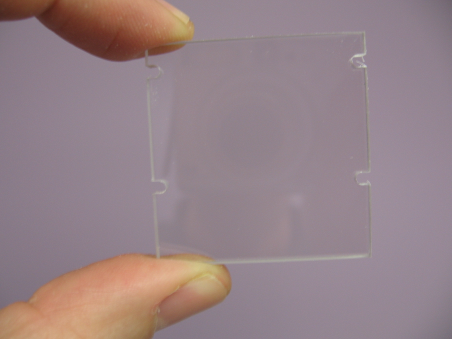

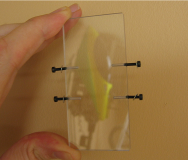

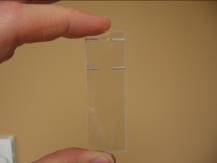

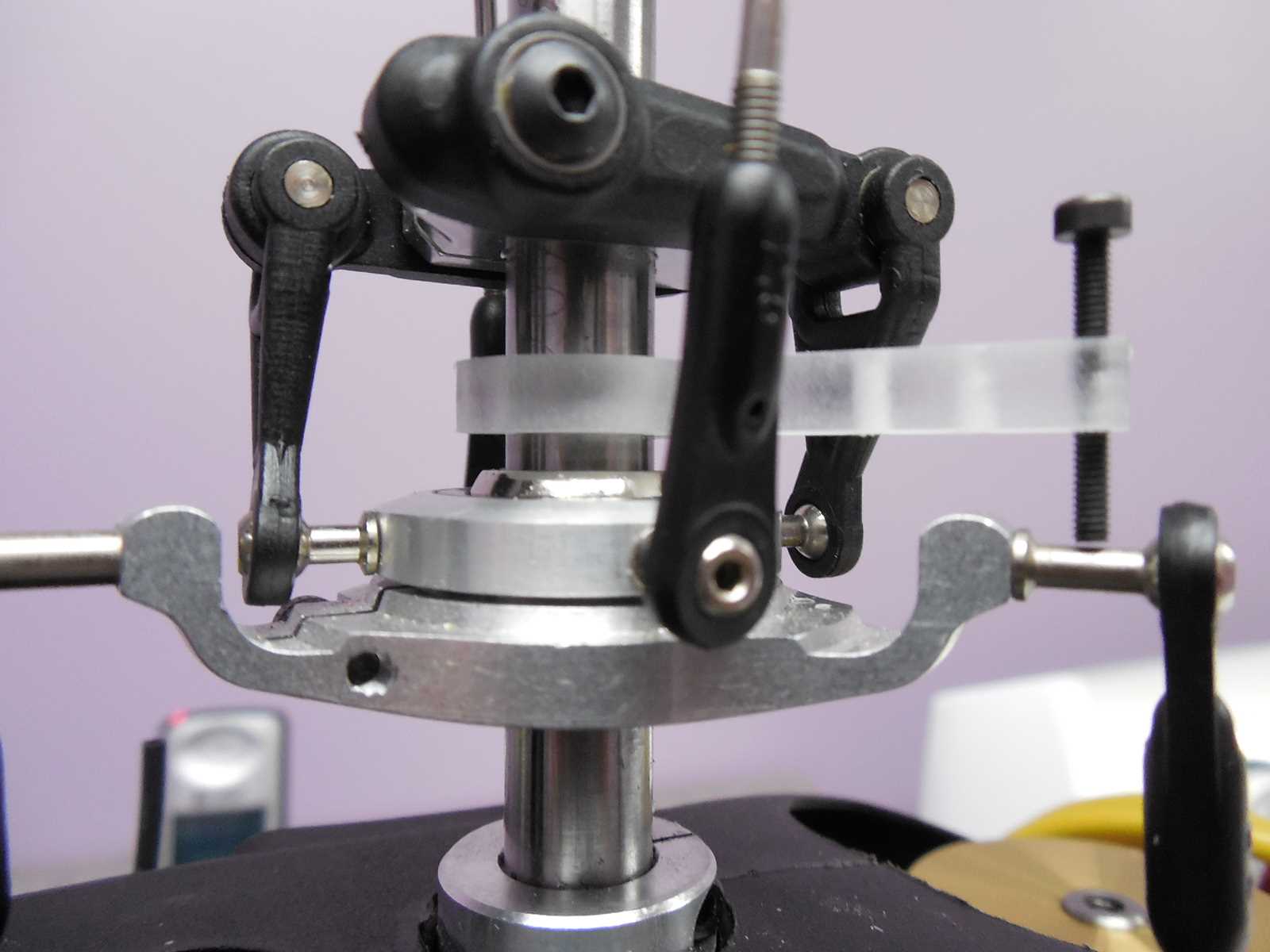

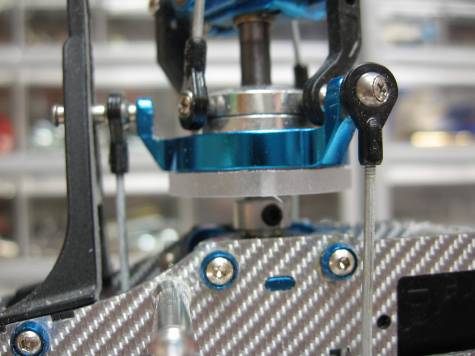

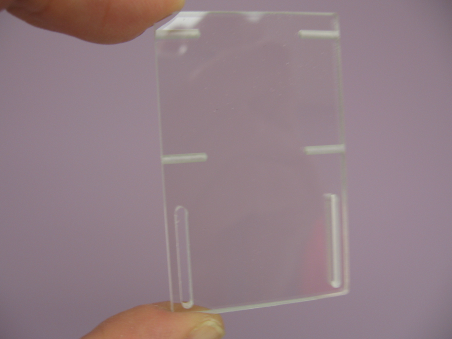

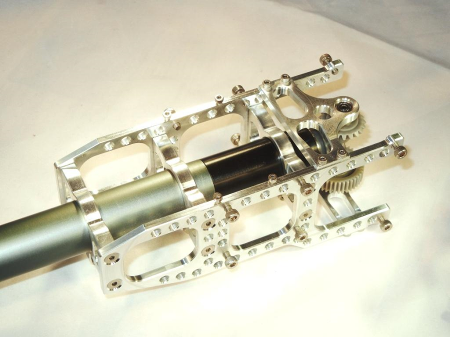

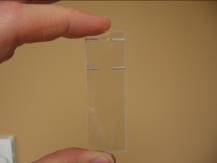

3.5 mm

Under Swash Leveling Tool (USLT) Patent Pending

This tool allows you to level your swash plate WITHOUT

removing the head. Lexan tool won�t scratch your heli.

Press fit the tool onto the main shaft just under or over the

swash plate and it provides a level surface to use as a reference while

leveling your swash. Once the tool is installed, turn it on the shaft a

few times to allow it to level itself. Spin the main shaft to verify it is

level and manually adjust if needed until the tool is perfectly level.

Avoid touching the tool once it is level. Tip the tool up or down while

removing to make removal easier.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Remember to remove tool when done with adjustments.

Some have attached a red ribbon to help them remember.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

5 mm

Under Swash Leveling Tool (USLT) Patent Pending

This tool allows you to level your swash plate WITHOUT

removing the head. Lexan tool won�t scratch your heli.

Press fit the tool onto the main shaft just under or over the

swash plate and it provides a level surface to use as a reference while

leveling your swash. Once the tool is installed, turn it on the shaft a

few times to allow it to level itself. Spin the main shaft to verify it is

level and manually adjust if needed until the tool is perfectly level.

Avoid touching the tool once it is level. Tip the tool up or down while

removing to make removal easier.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Remember to remove tool when done with adjustments.

Some have attached a red ribbon to help them remember.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

8 mm

Under Swash Leveling Tool (USLT) Patent Pending

This tool allows you to level your swash plate WITHOUT

removing the head. Lexan tool won�t scratch your heli.

Press fit the tool onto the main shaft just under or over the

swash plate and it provides a level surface to use as a reference while

leveling your swash. Once the tool is installed, turn it on the shaft a

few times to allow it to level itself. Spin the main shaft to verify it is

level and manually adjust if needed until the tool is perfectly level.

Avoid touching the tool once it is level. Tip the tool up or down while

removing to make removal easier.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Remember to remove tool when done with adjustments.

Some have attached a red ribbon to help them remember.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

10 mm

Under Swash Leveling Tool (USLT) Patent Pending

This tool allows you to level your swash plate WITHOUT

removing the head. Lexan tool won�t scratch your heli.

Press fit the tool onto the main shaft just under or over the

swash plate and it provides a level surface to use as a reference while

leveling your swash. Once the tool is installed, turn it on the shaft a

few times to allow it to level itself. Spin the main shaft to verify it is

level and manually adjust if needed until the tool is perfectly level.

Avoid touching the tool once it is level. Tip the tool up or down while

removing to make removal easier.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Remember to remove tool when done with adjustments.

Some have attached a red ribbon to help them remember.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

12 mm

Under Swash Leveling Tool (USLT) Patent Pending

This tool allows you to level your swash plate WITHOUT

removing the head. Lexan tool won�t scratch your heli.

Press fit the tool onto the main shaft just under or over the

swash plate and it provides a level surface to use as a reference while

leveling your swash. Once the tool is installed, turn it on the shaft a

few times to allow it to level itself. Spin the main shaft to verify it is

level and manually adjust if needed until the tool is perfectly level.

Avoid touching the tool once it is level. Tip the tool up or down while

removing to make removal easier.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Remember to remove tool when done with adjustments.

Some have attached a red ribbon to help them remember.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

14 mm

Under Swash Leveling Tool (USLT) Patent Pending

This tool allows you to level your swash plate WITHOUT

removing the head. Lexan tool won�t scratch your heli.

Press fit the tool onto the main shaft just under or over the

swash plate and it provides a level surface to use as a reference while

leveling your swash. Once the tool is installed, turn it on the shaft a

few times to allow it to level itself. Spin the main shaft to verify it is

level and manually adjust if needed until the tool is perfectly level.

Avoid touching the tool once it is level. Tip the tool up or down while

removing to make removal easier.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Remember to remove tool when done with adjustments.

Some have attached a red ribbon to help them remember.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

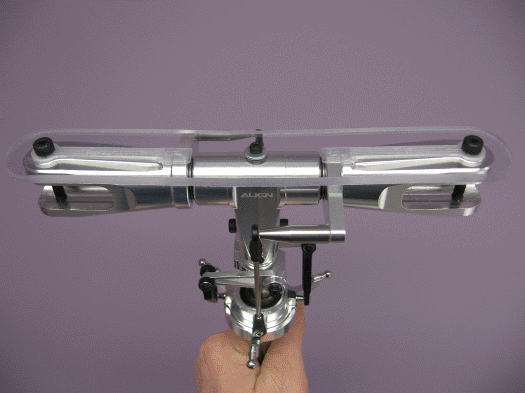

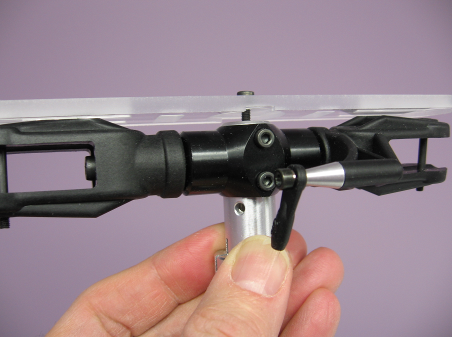

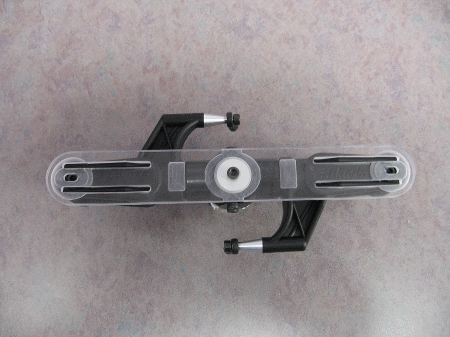

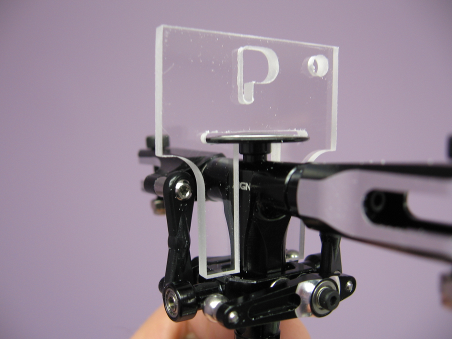

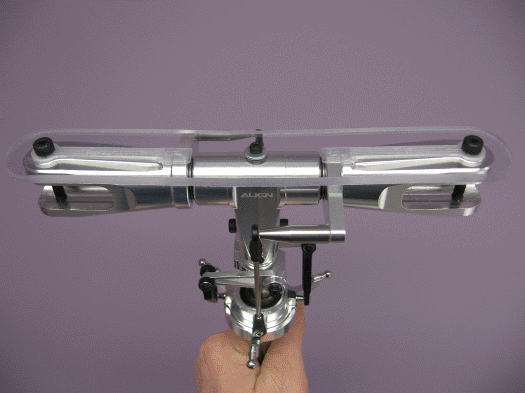

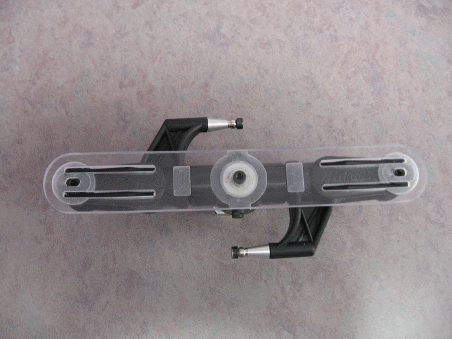

Universal

250 - 450 Zero Pitch Tool

This tool mounts on top the head and locks the blade grips at

zero pitch to allow easy adjustment of links. This tool will work for most

250 � 450 size heads with flat topped blade grips and tee. Lexan tool

won�t scratch your paint.

Use supplied washers between screw heads and tool and

avoid over tightening. Otherwise tool may be damaged.

Remove the head button. Use the head button screw(s) to

center the Zero Pitch tool and screw in just a few turns. Now turn the

blade grips to zero pitch and partially screw to the blade grips using the

blade grip screws. Now snug all screws till secure. May need additional

washers/paper under tool or longer screws as necessary to make all

surfaces level (not supplied). Now you can easily adjust your links.

Note: Additional screws/washers may be needed for some heads.

Use paper to protect the head from scratching. (Not supplied)

Note: Orient with milled channels down for grips with

protruding tops such as some TREX grips.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

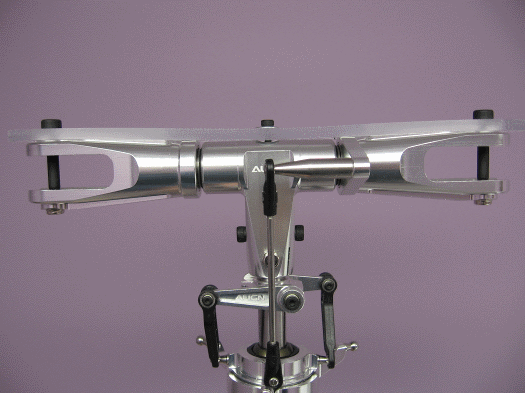

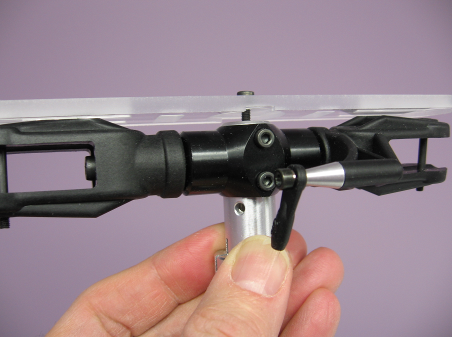

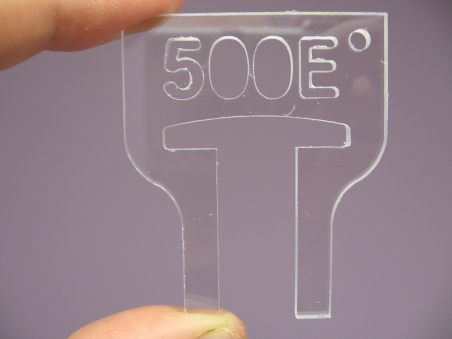

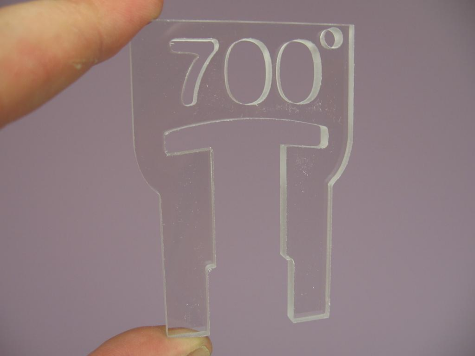

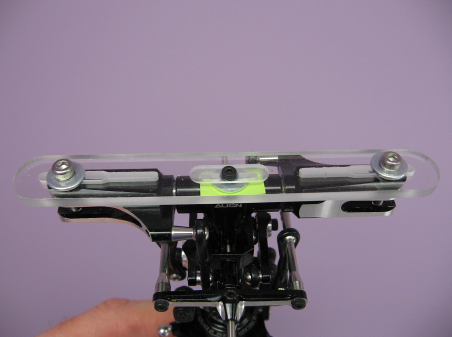

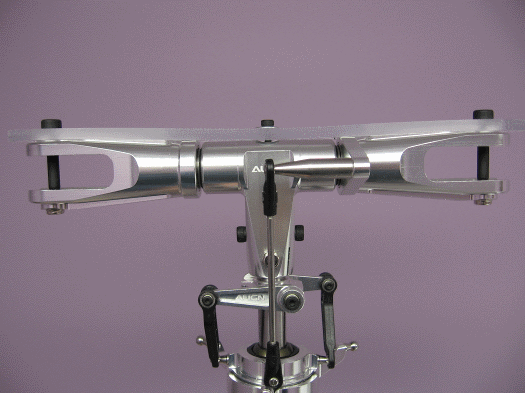

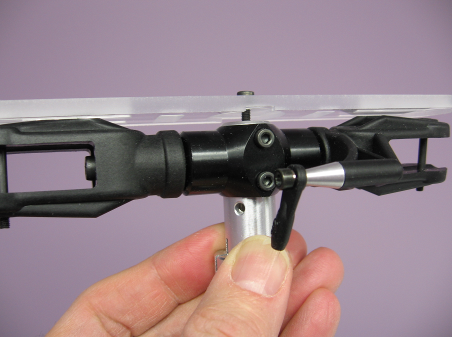

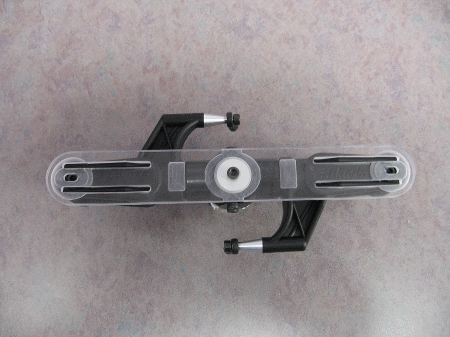

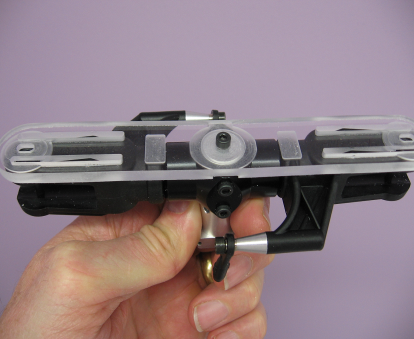

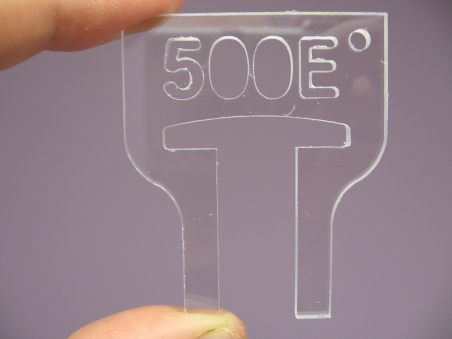

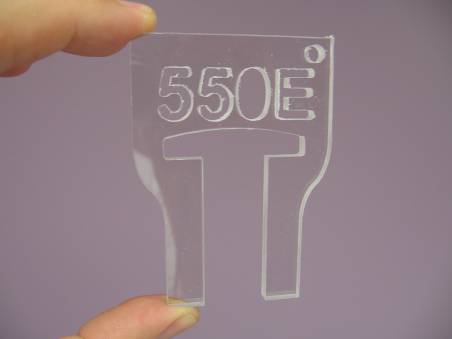

Universal

500 - 700 Zero Pitch Tool

This tool mounts on top the head and locks the blade grips at

zero pitch to allow easy adjustment of links. This tool will work for most

500 � 700 size heads with flat topped blade grips and tee. Lexan tool

won�t scratch your paint.

Use supplied washers between screw heads and tool and

avoid over tightening. Otherwise tool may be damaged.

Remove the head button. Use the head button screw(s) to

center the Zero Pitch tool and screw in just a few turns. Now turn the

blade grips to zero pitch and partially screw to the blade grips using the

blade grip screws. Now snug all screws till secure. May need additional

washers/paper under tool or longer screws as necessary to make all

surfaces level (not supplied). Now you can easily adjust your links.

Note: Additional screws/washers may be needed for some heads.

Use paper to protect the head from scratching. (Not supplied)

Note: Orient with milled channels down for grips with

protruding tops such as some TREX grips.

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

TREX 700

Zero Pitch Tool

This tool mounts on top the head and locks the blade grips at

zero pitch to allow easy adjustment of links. Blades can be on or off.

Lexan tool won�t scratch your paint.

Use supplied washers between screw heads and tool and

avoid over tightening. Otherwise tool may be damaged.

Remove the head button. Press the tool down over each blade

grip one at a time. Use the head button screw to stabilize the Zero Pitch

tool. Install blade grip screws if not secure enough. Now you can easily

adjust your links.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail or an Exacto knife.

Note: Edges can be sanded with 220 grit sand paper if there

are rough edges or burrs.

Logo 400

Zero Pitch Tool

This tool mounts on top the head and locks the blade grips at

zero pitch to allow easy adjustment of links. Blades can be on or off.

Lexan tool won�t scratch your paint.

Remove the head button. Use the head button screw to center

the Zero Pitch tool and screw in just a few turns. Now turn the blade

grips to zero pitch and slide the tool down over the ribs on top of the

grip till they are secure. Screw the tool down till it is snug. Over tightening will damage part.

Install blade grip screws if not secure enough. Now you can easily adjust

your links.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail or an Exacto knife.

Note: Edges can be sanded with 220 grit sand paper if there

are rough edges or burrs.

Logo 500

Zero Pitch Tool

This tool mounts on top the head and locks the blade grips at

zero pitch to allow easy adjustment of links. Blades can be on or off.

Lexan tool won�t scratch your paint. Fits Logo 400 as well.

Remove the head button. Use the head button screw to center

the Zero Pitch tool and screw in just a few turns. Now turn the blade

grips to zero pitch and slide the tool down over the ribs on top of the

grip till they are secure. Screw the tool down till it is snug. Over tightening will damage part.

Install blade grip screws if not secure enough. Now you can easily adjust

your links.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail or an Exacto knife.

Note: Edges can be sanded with 220 grit sand paper if there

are rough edges or burrs.

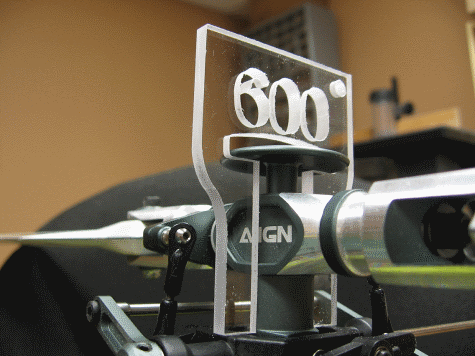

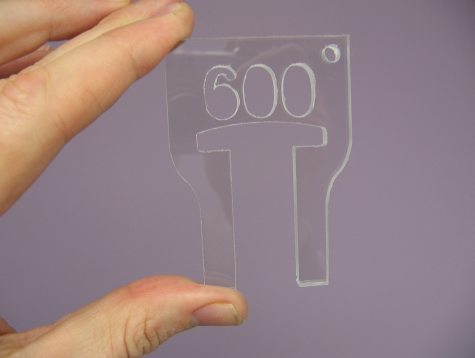

Logo 600

Zero Pitch Tool

This tool mounts on top the head and locks the blade grips at

zero pitch to allow easy adjustment of links. Blades can be on or off.

Lexan tool won�t scratch your paint.

Remove the head button. Slide the tool down over the ribs on

the top of the blade grips till they are secure while centering the tool

over the head button hole. Use the head button screw to tighten the Zero

Pitch tool down till it is snug. Over tightening

will damage part. Now you can easily adjust

your links.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail or an Exacto knife.

Note: Edges can be sanded with 220 grit sand paper if there

are rough edges or burrs.

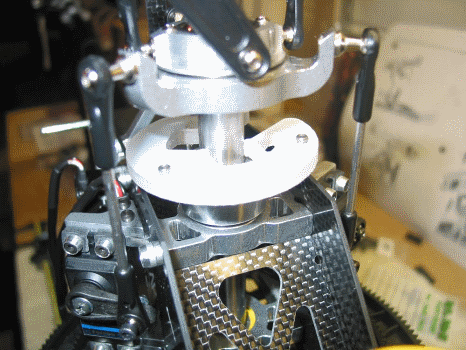

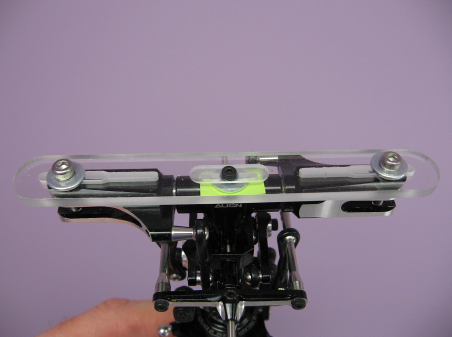

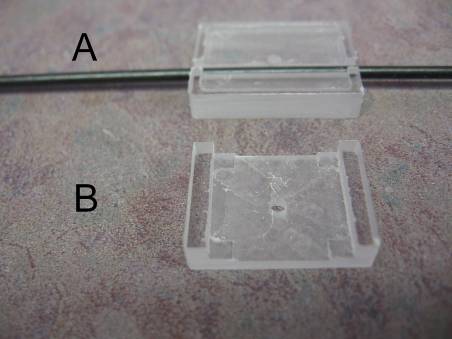

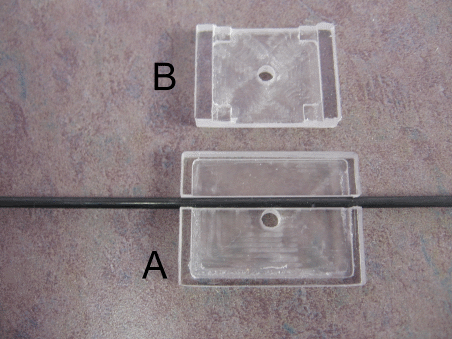

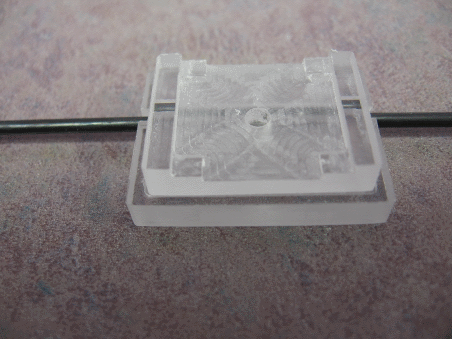

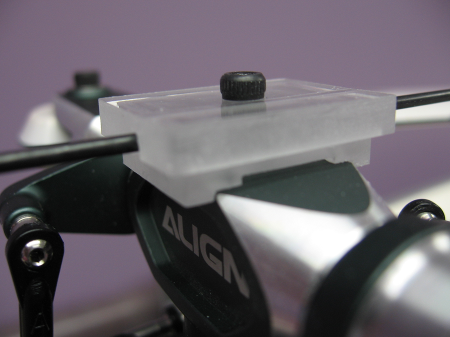

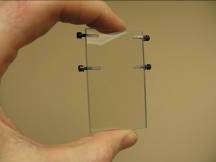

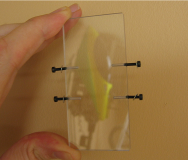

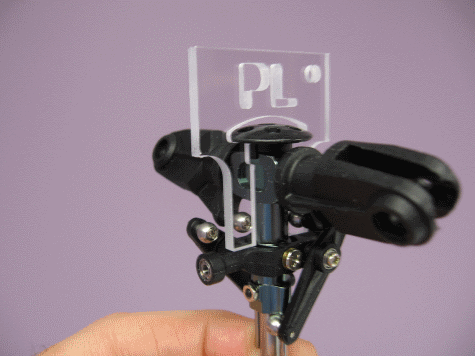

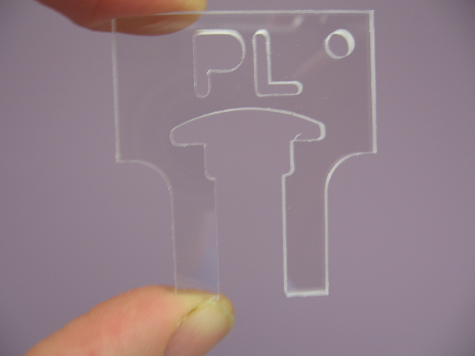

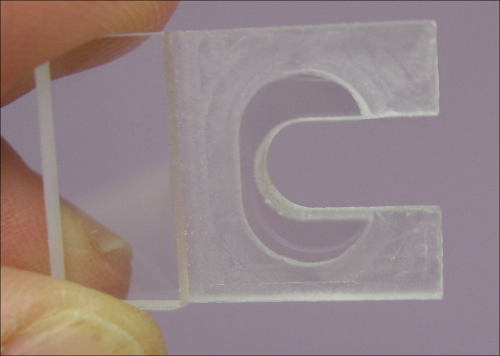

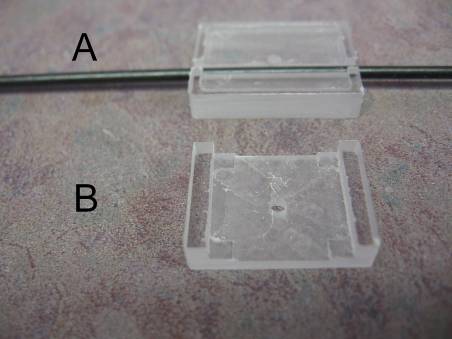

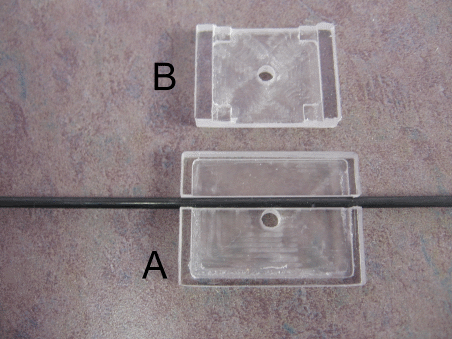

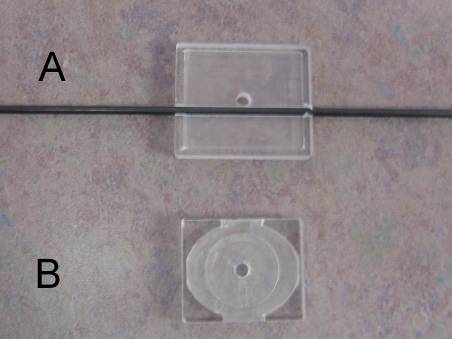

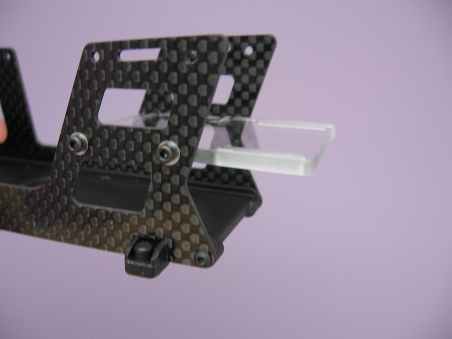

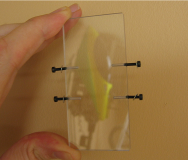

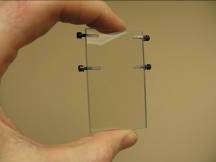

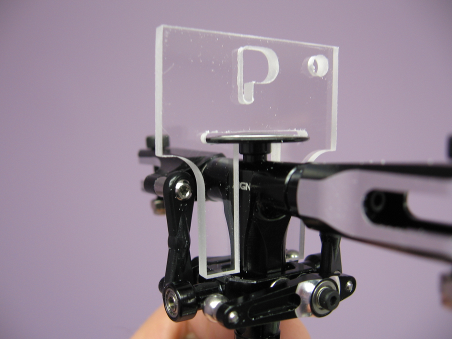

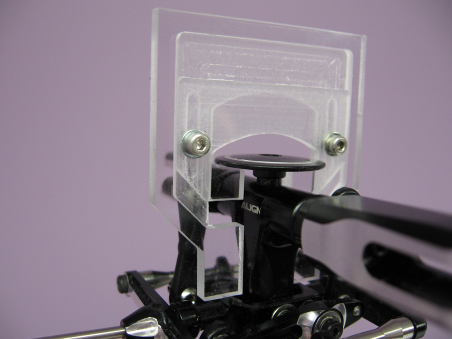

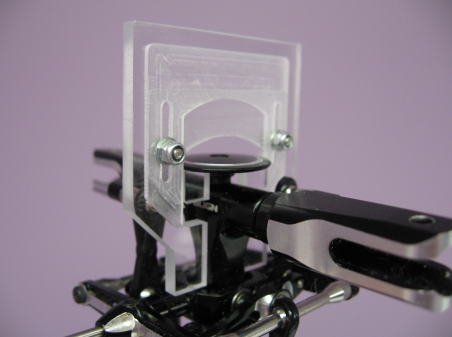

TREX 500

FBL Pitch Alignment Tool

This tool mounts on top the head to provide a level reference

for your pitch gauge to allow accurate blade pitch adjustments on

Flybarless heads. A TREX 450 Flybar is used as reference bar (not

included). Lexan tool won�t scratch your paint.

Center a 450 flybar (not included) into the slotted top piece

(Part A). Place the head mount (Part B) over the flybar and top piece

(Part B), feet side up. Mount the assembly onto the head assuring the feet

rest evenly as shown. Screw gently into place with the head button screw

(not included). Over tightening will damage

part. Now your pitch gauge can be sighted

along the 450 flybar.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail an Exacto knife.

Note: Edges can be sanded with 220 grit

sand paper if there are rough edges or burrs.

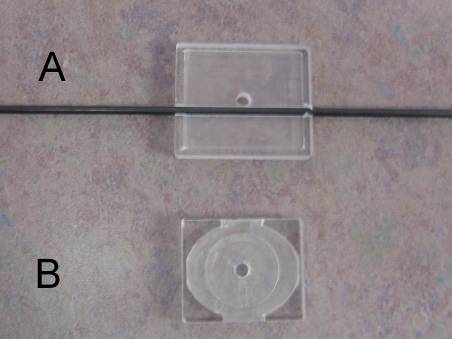

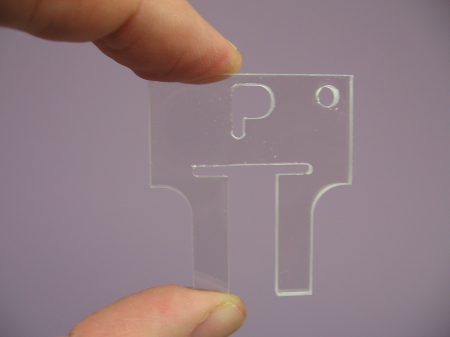

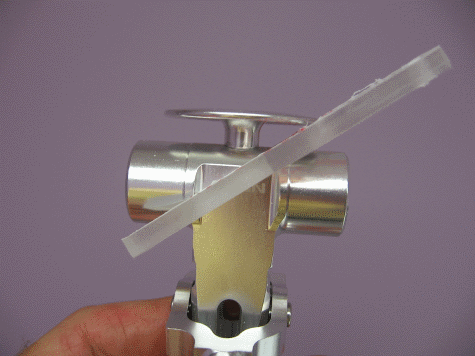

TREX 600

FBL Pitch Alignment Tool

This tool mounts on top the head to provide a level reference

for your pitch gauge to allow accurate blade pitch adjustments on

Flybarless heads. A TREX 450 Flybar is used as reference bar (not

included). Lexan tool won�t scratch your paint.

Center a 450 flybar (not included) into the slotted top piece

(Part A). Place the head mount (Part B) over the flybar and top piece

(Part B), feet side up. Mount the assembly onto the head assuring the feet

rest evenly as shown. Screw into place with the head button screw (not

included). Now you pitch gauge can be sighted along the 450 flybar.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail an Exacto knife.

Note: Edges can be sanded with 220 grit

sand paper if there are rough edges or burrs. .

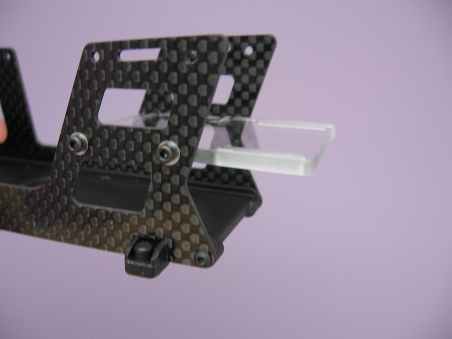

Logo FBL

Pitch Alignment Tool

This tool mounts on top the head to provide a level reference

for your pitch gauge to allow accurate blade pitch adjustments on

Flybarless heads. A TREX 450 Flybar is used as reference bar (not

included). Lexan tool won�t scratch your paint.

Center a 450 flybar (not included) into the slotted top piece

(Part A). Place the head mount (Part B) over the flybar and top piece

(Part B), feet side up. Mount the assembly onto the head assuring the feet

rest evenly as shown. Screw gently into place with the head button screw

(not included). Over tightening will damage

part. Now your pitch gauge can be sighted

along the 450 flybar.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail an Exacto knife.

Note: Edges can be sanded with 220 grit sand paper if there

are rough edges or burrs.

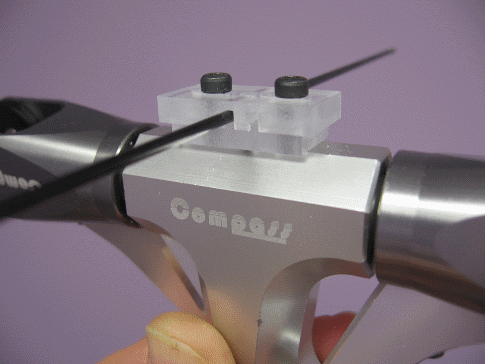

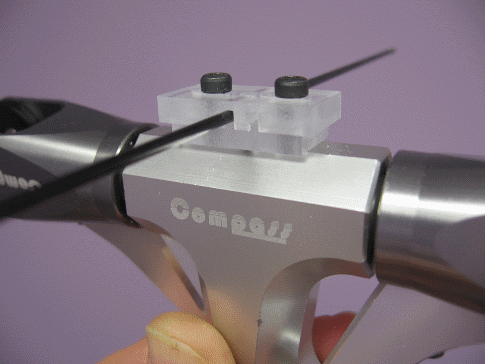

Compass

6HV FBL Pitch Alignment Tool

This tool mounts on top the head to provide a level reference

for your pitch gauge to allow accurate blade pitch adjustments on

Flybarless heads. A TREX 450 Flybar is used as reference bar (not

included). Lexan tool won�t scratch your paint.

Center a 450 flybar (not included) into the slotted top piece

(Part A). Place the head mount (Part B) over the flybar and top piece

(Part A). Mount the assembly onto the head. Screw gently into place with

the head button screws (not included). Over

tightening will damage part. Now your pitch

gauge can be sighted along the 450 flybar.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail or an Exacto knife.

Note: Edges can be sanded with 220 grit sand paper if there

are rough edges or burrs.

TREX 450

Sport Gyro/Receiver Mount

This mount provides an additional rigid mounting surface for

your gyro, receiver, or both.

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a gyro mid flight will make

for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Clean any machine oil off the screws before

installation

Note: For additional security, add a touch of CA when installing the

screws (Optional)

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

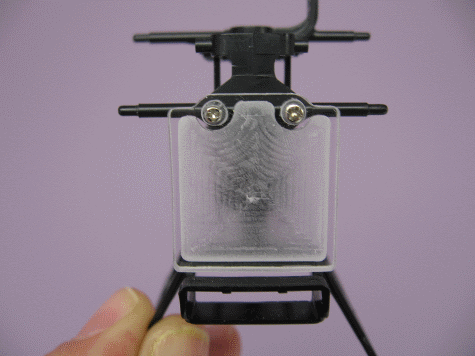

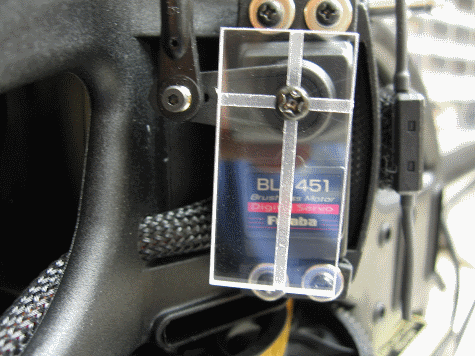

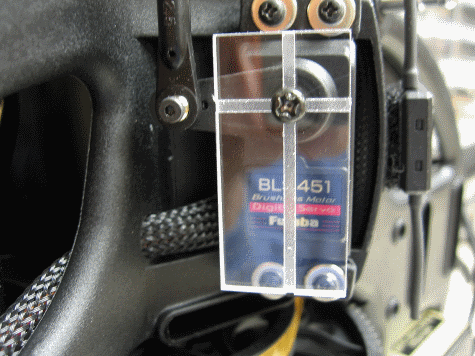

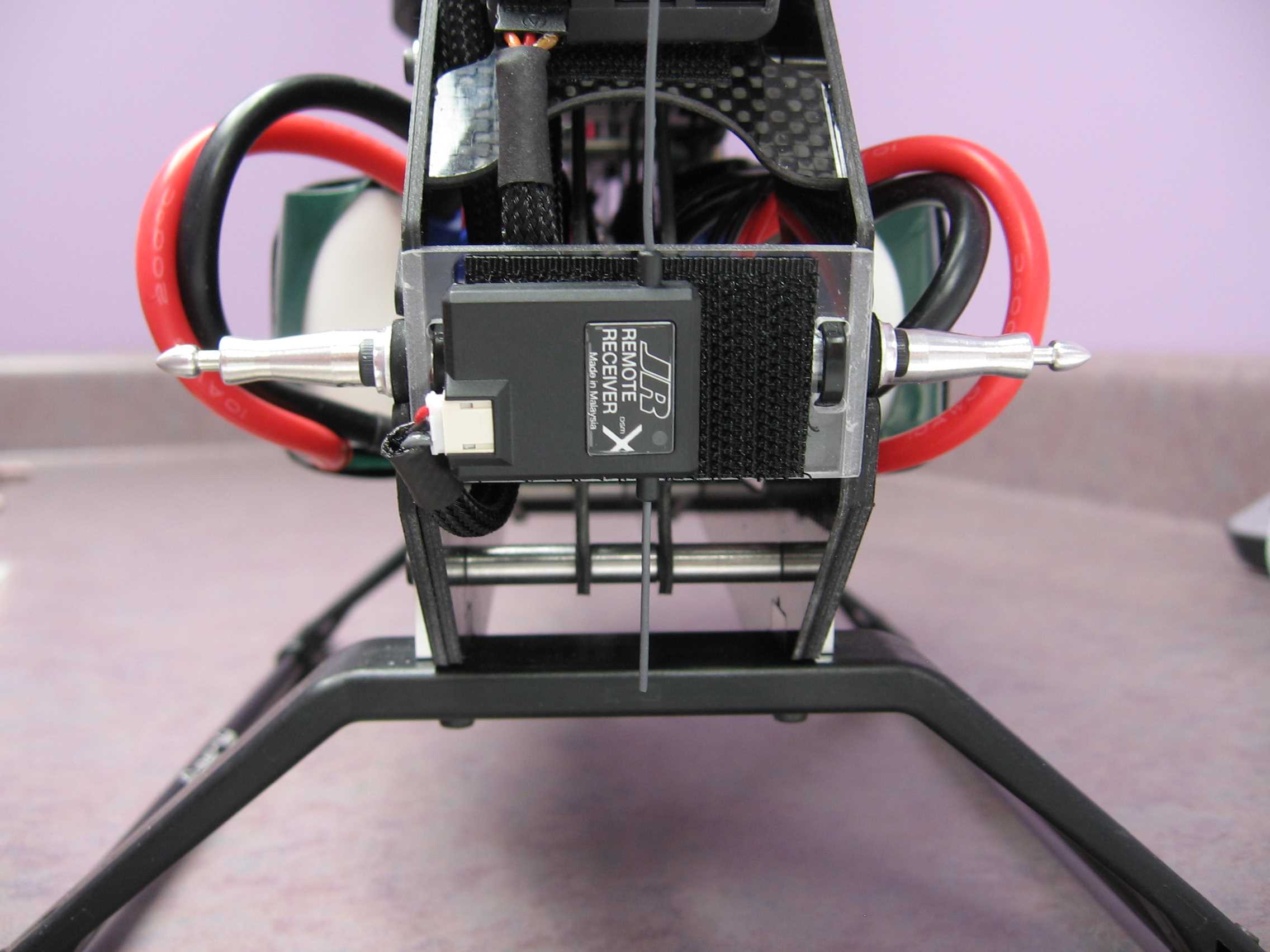

TREX 500

Gyro/Receiver Mount

This mount provides an additional rigid mounting surface for

your gyro, receiver, or both. (Inspired by ChasHeliCop)

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a gyro mid flight will make

for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Clean any machine oil off the screws before

installation

Note: For additional security, add a touch of CA when installing the

screws (Optional)

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

TREX 500

VBAR Mount

This mount provides an additional rigid mounting surface for

your VBAR, gyro, receiver, or both. (Inspired by Steven Bales)

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a component mid flight will

make for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Clean any machine oil off the screws before

installation

Note: For additional security, add a touch of CA when installing the

screws (Optional)

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

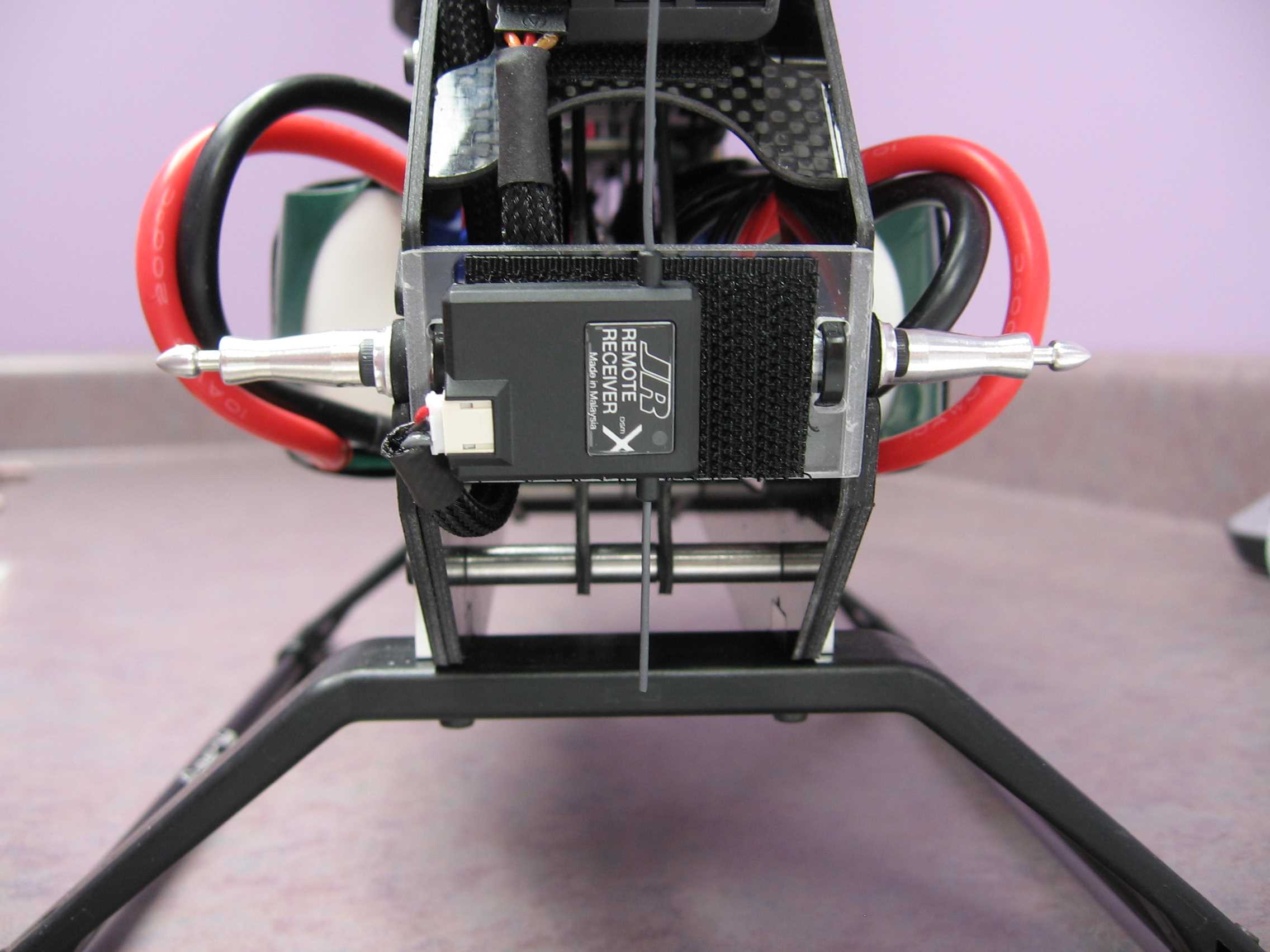

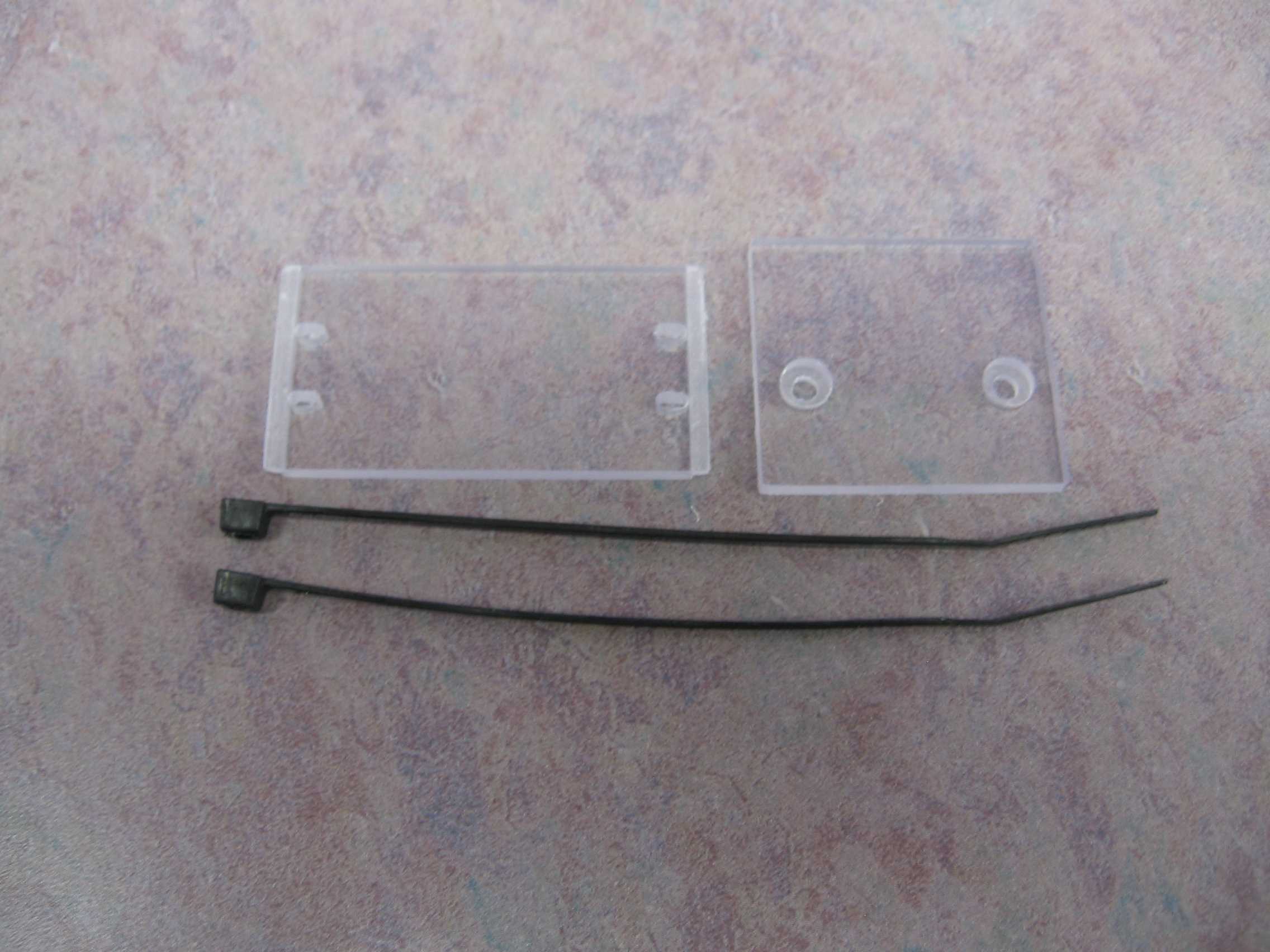

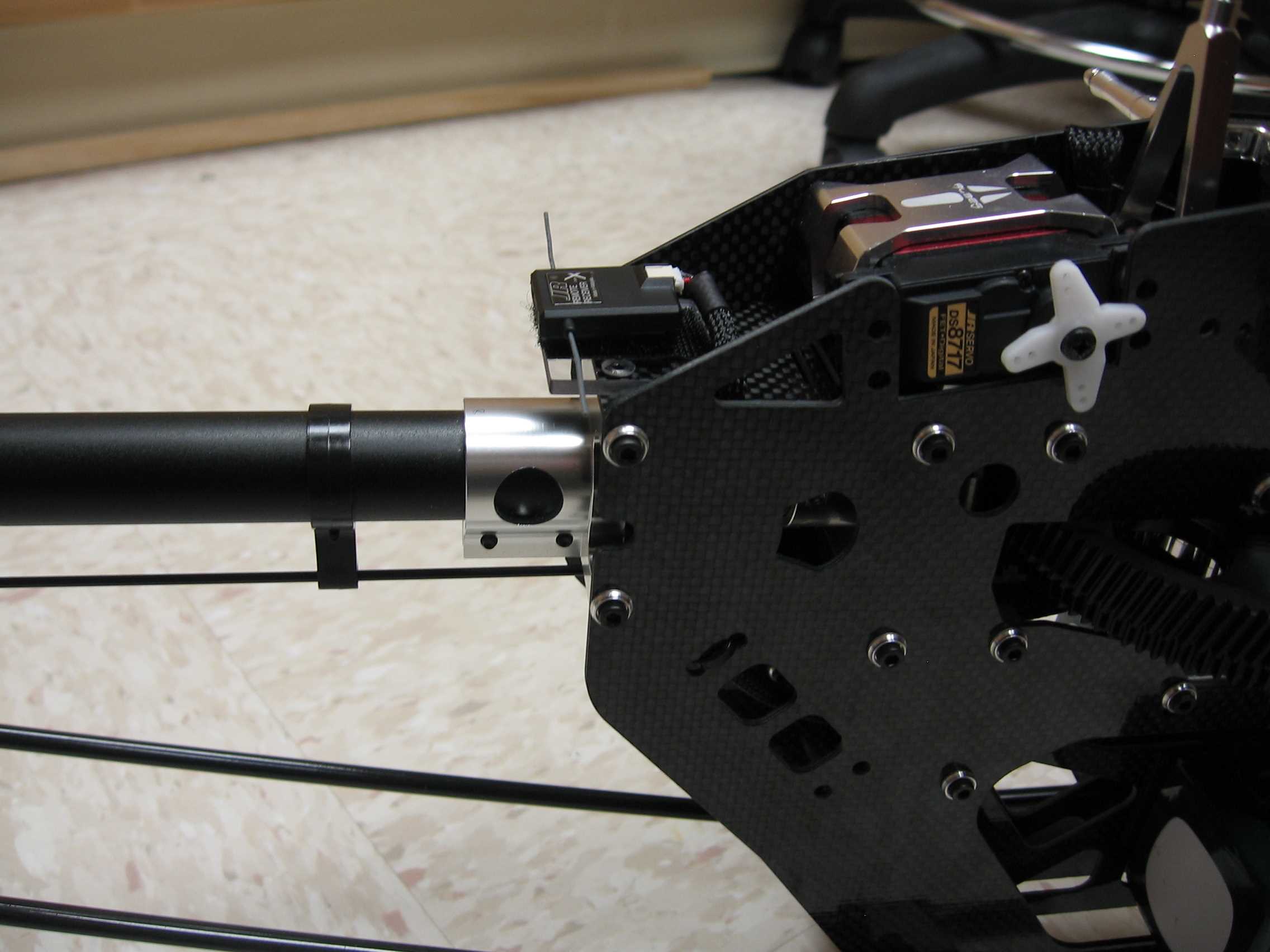

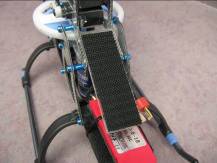

Rush 750

Satellite Receiver Mounts

Light weight non-conductive mounting surfaces that allow

optimum placement of your satellite receiver units.

Rear Unit: Mount using stock screws from boom mount assembly.

Unit can be rotated to provide a shorter or longer mount. Longer mount is

recommended for better isolation from conductive surfaces.

Front Unit: Mount using provided nylon ties. Prior to

installation, insert nylon ties from back through upper slots then loop

back through lower slots. Start tie end around heli metal spacer and

through the nylon locks then snap mount into place. Finish by tightening

locks then trim excess nylon. Mount Satellite Receiver with your adhesive

of choice (not provided). Center the antennas for optimum placement.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

mCP X

3-n-1 Mount (for Controller Module)

This mount provides a light weight, vibration isolated, rigid

mounting surface for your Flybarless 3-n-1 Control Unit.

Assure all servo wires are loose enough to move the 3-n-1

board forward at least an eighth of an inch. You may have to re-route the

wires from your rear servo just a little. Assure all 3-n-1 connectors are

glued in tightly. Slip the slots in the back side of the mount over the

mounting tubes for the 3-n-1 board. Use the 3-n-1 stock mounting screws

with a dab of CA on the threads to secure the mount to the tubes.

Carefully place a square of medium thickness gyro mounting foam (not

included) over the smooth side of the mount. Firmly and slowly squeeze the

foam against the mount for about 10 seconds to get a solid bond. Carefully

center and stick your 3-n-1 unit onto the new mount making sure the bottom

of the 3-n-1 board lines up with the bottom of the mount to assure proper

canopy fit above the board. Again, firmly and slowly squeeze the foam

against the 3-n-1 for about 10 seconds to assure no gaps and a solid bond.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Milling artifacts can be removed by scraping carefully

along the edges with a fingernail, Exacto knife or 220 sand paper.

Ultimate

TREX 500 Gyro Mount

This mount provides rigid mounting surface for your gyro.

(Designed by BobOD)

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a gyro mid flight will make

for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

Ultimate

TREX 550E/600E Gyro Mount

This mount provides rigid mounting surface for your gyro.

(Designed by BobOD)

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a gyro mid flight will make

for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

Ultimate

TREX 550N/600N Gyro Mount

This mount provides rigid mounting surface for your gyro.

(Designed by BobOD)

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a gyro mid flight will make

for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

TREX 600

Gyro/Receiver Mount

This mount provides an additional rigid mounting surface for

your gyro, receiver, or both.

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a gyro mid flight will make

for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Clean any machine oil off the screws before

installation

Note: For additional security, add a touch of CA when installing the

screws (Optional)

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

TREX 600

VBAR Mount

This mount provides an additional rigid mounting surface for

your VBAR, gyro, receiver, or both. (Inspired by Tony DeCrosta)

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a component mid flight will

make for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Clean any machine oil off the screws before

installation

Note: For additional security, add a touch of CA when installing the

screws (Optional)

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

TREX 450

Battery Mount

This mount provides a strong flexible mounting surface for

your battery. (Inspired by copterklutz)

Mount in place of stock battery tray. Use stock screws to

mount. Once you place Velcro on top for your battery it will raise the

mounting surface to the height of the frame edges. Be very careful placing

Velcro because it sticks very well to the Lexan!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Clean any machine oil off the screws before

installation

Note: For additional security, add a touch of CA when installing the

screws (Optional)

TREX 500

Battery Mount

This mount provides a rigid mounting surface for both your

battery and ESC. Mounting hardware included (Inspired by chuckk)

Mount in place of stock battery tray. Use stock silver bling

and canopy standoffs. Put Velcro on top for your battery and Velcro

underneath for your ESC. Be very careful placing Velcro because it sticks

very well to the Lexan!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: Clean any machine oil off the screws before

installation

Note: For additional security, add a touch of CA when

installing the screws (Optional)

Inverted

Gyro Mount (The Thingy)

Its intent is to allow you to

securely mount the gyro underneath the boom so as to avoid damage to the

gyro by an out of control flybar or blade if you crash. Mounts are

available for the TREX SE, XL, SA, SuperFrame, and Mini-Titan.

SE Inverted Mount XL Inverted Mount

SuperFrame Mount SA Inverted Mount Mini-Titan Mount

There are 4 main approaches to

mounting the Inverted Gyro Mount:

- Glue the Inverted Gyro

Mount in place. (SA, SE, XL & SuperFrame mounts)

Use Plumbers Goop to secure. Adhere

to as many surfaces as possible to give the best grip. Avoid getting goop

on the boom since you will want to adjust it periodically.

- Screw it into the boom

block through the bottom of the Inverted Gyro Mount. (SE mount

only)

This method requires you to drill

one hole through the boom block, and then tap the hole with a 3mm .50

pitch tap. Press the block into place and use it as a template to drill a

#40 hole. Only drill through the first layer of metal which is only a few

mm thick. Carefully tap the hole with a 3 mm .50 pitch tap. Use loctite on

screw when installing. Make it snug but do not over tighten or you could

break the bond between the inner block and the top block. You don�t want

to strip the hole or damage the Inverted Gyro Mount.

I will drill the countersunk hole

in the Inverted Gyro Mount and provide a 3mm stainless steel mounting

screw if requested when ordering.

- Screw into the Inverted

Gyro Mount from both sides through the frame. (SE & SuperFrame mounts )

This method requires you drill a

hole through your frames on each side. Screws will go through your frames

into the small block on the Inverted Gyro Mount. Drill the frames first.

Locate the new holes directly between the two existing holes. Use a bit

that matches the other holes in the frame.

Press the mount into place, and then

use the frame holes to drill smaller holes into the small block on the

mount. Use a bit sized appropriately for your screws. Drill very slowly

making sure to keep the drill perpendicular to the frame. Drill a separate

hole for each side, rather than one hole clear through the block.

- Stick on the Inverted

Gyro Mount with double sided tape. (All mounts )

Use a thin 1/16�heavy duty double

sided mounting tape like Scotch� Exterior Mounting Tape. Don�t use the

1/8� spongy type that comes with your gyro to mount the Gyro Mount because

it will make the gyro response a bit mushy.

Whatever method you choose, be very careful that all is

secure. A safety strap of some kind is recommended for added security.

Losing a gyro mid flight will make for a very challenging landing and

could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: If one clear edge is longer than the other, place the

longer end out to make sure there is plenty of room to mount the gyro.

Note: Reverse the �Dir� switch on your gyro if moving

it from the top to down under or spinning will occur.

Gaui 200

Gyro/Receiver Mount

This mount provides an additional rigid mounting surface for

your gyro, receiver, or both. (Inspired by BuzzKill)

Be very careful that all is secure. A safety strap of some

kind is recommended for added security. Losing a gyro mid flight will make

for a very challenging landing and could be dangerous!

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded with 220 grit sand paper if the fit

is too tight or if there are rough edges or burrs.

Note: A little soap on the threads will make it easier to

turn in the screws. They are purposely tight.

Note: Reverse the �Dir� switch on your gyro if

inverting it or spinning will occur.

TREX 250

Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 450

Plastic Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to mid stick with the levers all parallel.

Install the Flybar Lock by sliding it in from the side down to touch the

seesaw on both sides of the Main Rotor Housing. Then slide the top over

the head button to secure in place.

Assure it is centered between the linkages so that they all

move freely. Adjust pitch back to mid stick to remove when adjustments are

complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the

fit is too tight or if there are burrs on the edges

TREX 450

V1 Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. This tool will not work on late model V1s with the V2

style button. Lexan tool won�t scratch your paint.

Adjust your head to mid stick with the levers all parallel.

Install the Flybar Lock by sliding it in from the side down to touch the

seesaw on both sides of the Main Rotor Housing. Then slide the top over

the head button to secure in place.

Assure it is centered between the linkages so that they all

move freely. Adjust pitch back to mid stick to remove when adjustments are

complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the

fit is too tight or if there are burrs on the edges

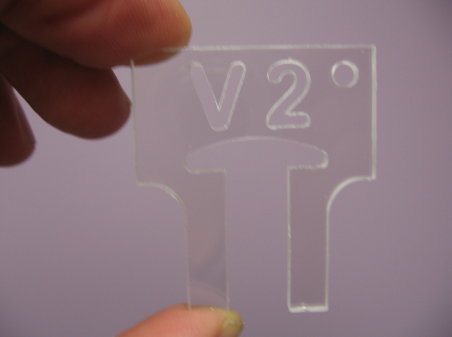

TREX 450

V2 Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. This tool also works on the late version V1 with the V2

style button. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

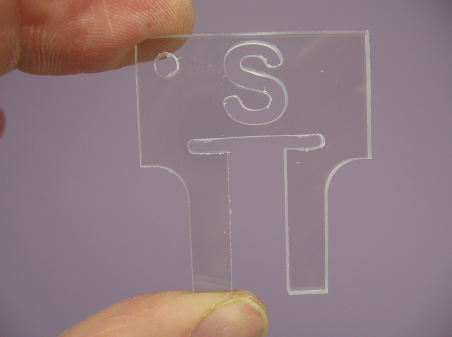

TREX 450

Sport Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the seesaw to secure in place. Remember

to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 450

Pro Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

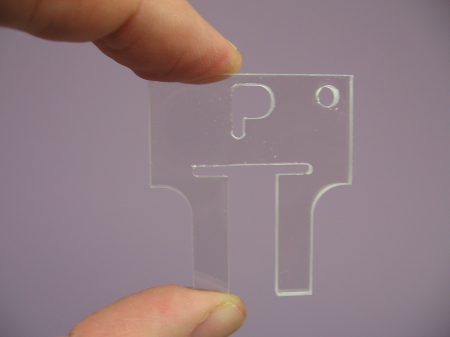

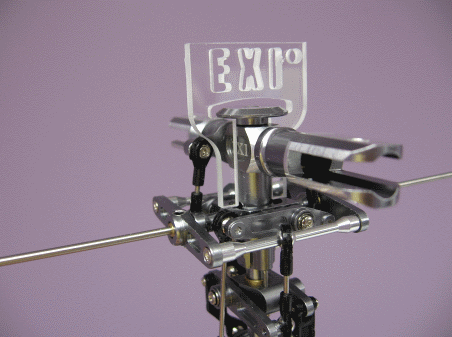

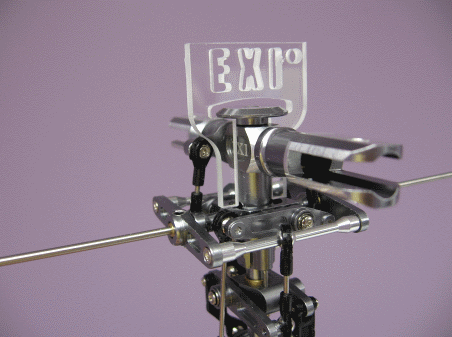

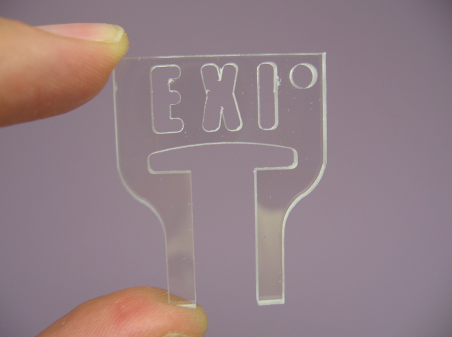

EXI 450

Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to mid stick with the levers all parallel.

Install the Flybar Lock by sliding it in from the side down to touch the

seesaw on both sides of the Main Rotor Housing. Then slide the top over

the head button to secure in place.

Assure it is centered between the linkages so that they all

move freely. Adjust pitch back to mid stick to remove when adjustments are

complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the

fit is too tight or if there are burrs on the edges

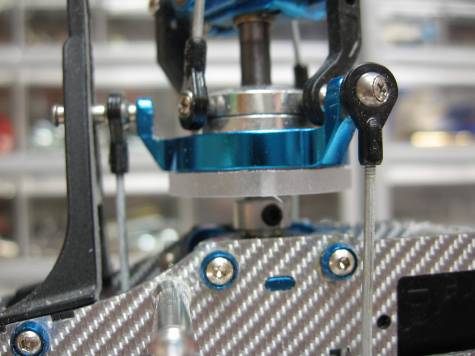

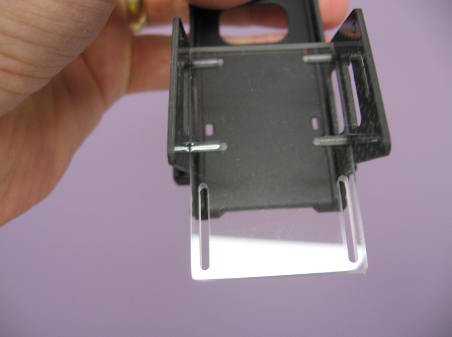

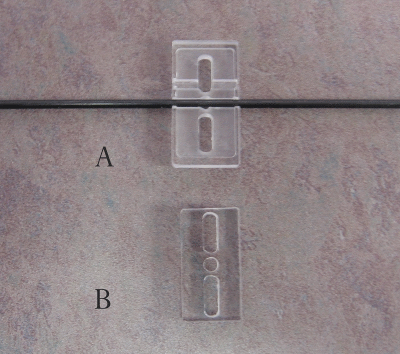

Adjustable

450 Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. It is adjustable to fit TREX 450 series and similar

heads. Adjust it for your 450 head making it snug without flexing the

legs. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Move the slider down to a spot that allows it to be slipped over

the button. Then move the slider up under the button till the lock is

secure and gently snug up the screws. Remove the lock and loosen one screw

at a time while shifting the slider up just a hair and snugging the screw

back up. Try the lock on the head again and repeat until the lock produces

a solid lock but is not hard to install and remove. Assure both sides are

even.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

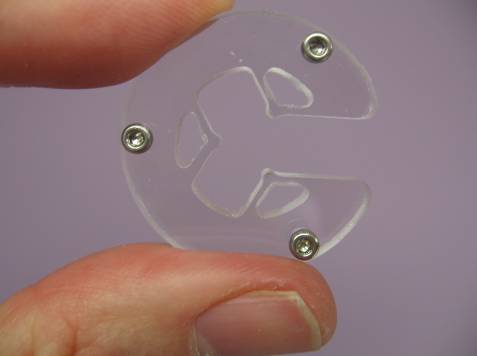

Adjustable

500 Flybar Lock (Fits TREX 500 series and similar heads)

This tool locks your flybar firmly in place while you adjust

your pitch ranges. It is adjustable to fit TREX 500 series and similar

heads. Adjust it for your 450 head making it snug without flexing the

legs. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Move the slider down to a spot that allows it to be slipped over

the button. Then move the slider up under the button till the lock is

secure and gently snug up the screws. Remove the lock and loosen one screw

at a time while shifting the slider up just a hair and snugging the screw

back up. Try the lock on the head again and repeat until the lock produces

a solid lock but is not hard to install and remove. Assure both sides are

even.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 500

Flybar Lock (fits heads with plastic seesaw)

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 500

ESP Flybar Lock (fits heads with the metal seesaw)

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

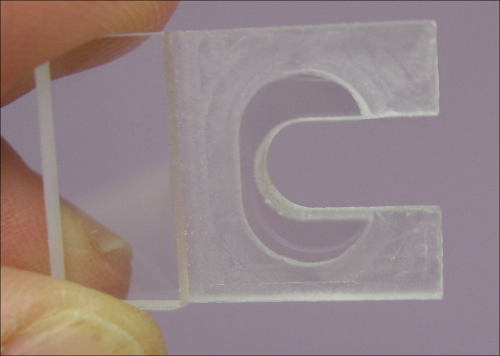

TREX

500E Pro Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Tilt your see saw down on one side then center your flybar

and slip the lock into place as shown. Push in till flush. Remember to

remove when adjustments are complete. Rock the tool back and forth to

remove. Removal gets easier as the tool breaks in. Apply a bit of oil to

contact surfaces if installation/removal is too difficult.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 550

ESP Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

Outrage

550 Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Tilt your flybar and slip the half moon lock piece into one

side as shown. Now, flip the head over and swing the flybar to 90 degrees

against the previously inserted lock. Insert the second half moon lock

piece into the opposite side. Now slide the latch over both to squeeze

them together. Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

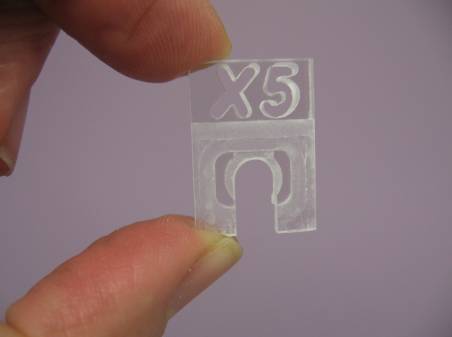

Gaui X5

Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Tilt your see saw down on one side then center your flybar

and slip the lock into place as shown. Push in till flush. Remember to

remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 600

Flybar Lock (fits original plastic and original metal seesaws)

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

(Get 600E version for 600 ESP helis with lighter seesaw like

black seesaw in far right picture.)

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 600

ESP Flybar Lock (fits latest lighter metal seesaws)

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

(Get 600 version for 600 helis with plastic or original metal

seesaw like green seesaw in far right picture.)

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side down to touch the seesaw on both sides of the Main Rotor

Housing. Then slide the top over the head button to secure in place.

Remember to remove when adjustments are complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 700

Flybar Lock

This tool locks your flybar firmly in place while you adjust

your pitch ranges. Lexan tool won�t scratch your paint.

Adjust your head to move the link down out of the way on the

side you are installing the lock on. Install the Flybar Lock by sliding it

in from the side between the button and the Main Rotor Housing (as shown

in first picture). Then slide it upright over the button to lock in place

between the button and the seesaw. Remember to remove when adjustments are

complete.

Note: Peel protective paper off all Lexan before use (if

there is any)

Note: Edges can be sanded or filed if the fit is too tight or

if there are burrs on the edges

TREX 450

Night Fins (1 Horizontal and 1 Vertical)

Make it easy to see the orientation of your night heli with

these high quality Lexan fins specially designed to make the most of cold

light strings. (Light strings and mounting hardware not included)

Thread the light string through the hole from back to front.

Leave plenty of slack to inlay the string. Start inlaying the string into

the slot placing the end next to the hole, and then progressively press

into the slot ending up back by the hole. Pull the excess string through

the hole. Use the handle of a screw driver on a hard surface to gently

press in string on corners. Use tiny drops of glue in slot to secure if

necessary. Use TREX screw bling or a washer when installing to avoid

stressing holes. Use loc-tite and just snug up screws. Over tightening

will damage fins.

Note: Drill additional 3/32� holes in slot if desired.

Note: A belt sander with 120 grit paper

can be used to touch up burnishing if necessary

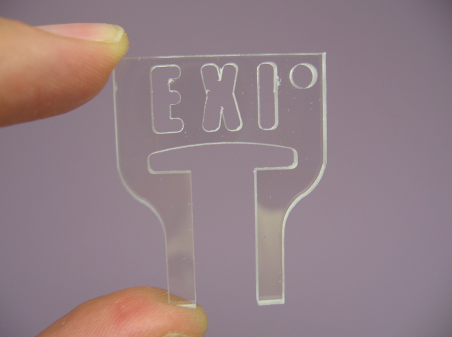

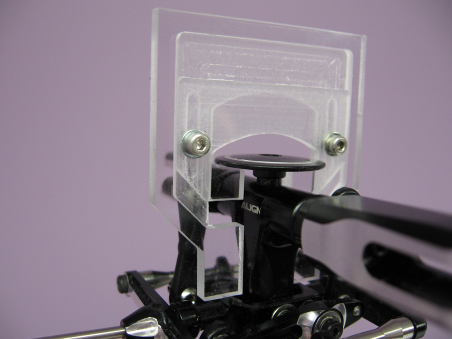

TREX 450

Night Fins w/Slotted Text (1 Horizontal and 1 Vertical)

Make it easy to see the orientation of your night heli with

these high quality Lexan fins specially designed to make the most of cold

light strings. (Light strings and mounting hardware not included)

Thread the light string through the hole from back to front.

Leave plenty of slack to inlay the string. Start inlaying the string into

the slot placing the end next to the hole, and then progressively press

into the slot ending up back by the hole. Pull the excess string through

the hole. Use the handle of a screw driver on a hard surface to gently

press in string on corners. Use tiny drops of glue in slot to secure if

necessary. Use TREX screw bling or a washer when installing to avoid

stressing holes. Use loc-tite and just snug up screws. Over tightening

will damage fins.

Note: Drill additional 3/32� holes in slot if desired.

Note: A belt sander with 120 grit paper

can be used to touch up burnishing if necessary

Slotted Finless Fins & 3D Fins

Stop replacing those stock fins on

the simplest crashes!

These fins are much more durable

than the stock fins and they look great. They survive most crashes that

would explode stock fins. They can however be scratched and they sometimes

get stress cracks if tightened too much or during some crashes. Be sure to

use SE bling or

equivalent sized washers

when screwing in or you can cause stress cracks. Do not over tighten, make

snug and use Loctite. They are made of the same material as plastic

eyeglass lens, so to keep them looking great, use care when handling. Wash

carefully with water and pat dry rather than rubbing.

Note: Peel protective paper off all

Lexan before use (if there is any)

Note: Edges can be sanded with 220

grit sand paper if there are burrs or they get marred

Note: Wash off any white powder or

dirt with water, lightly dry with paper towel.

Copyright 2006 - 2025 RDLohr's Clearly Superior Products. All rights reserved.